Category: Gun Info for Rookies

Bryan Hagerich with his family. Bryan Hagerich Family Photo

Bryan Hagerich with his family. Bryan Hagerich Family PhotoThe months-long saga for at least one American trapped on the island of Turks and Caicos (TCI) after airport security there discovered loose rounds of ammunition in his travel bag seems to be finally coming to end. A TCI judge today issued a suspended 52-month sentence to Bryan Hagerich, a Pennsylvania father of two and former professional baseball player, for possessing the ammunition. Hagerich, who pleaded guilty, was also fined $6,500. According to Fox News, he is expected to be released soon.

Hagerich is one of five Americans arrested in TCI since February for having stray ammunition in their luggage, a crime that can result in up to 12 years in prison under TCI law. The other Americans facing similar charges include Ryan Watson of Oklahoma, Sharitta Grier of Florida, Tyler Wenrich of Virginia, and Michael Lee Evans of Texas. Hagerich had stray rounds in his bag from a previous hunting trip that he wasn’t aware was even in the bag. Nor was it detected by TSA when he flew out of the United States.

“From the day that I was arrested, the end goal was to get off the island and go home to my family. To think that day is potentially tomorrow, it’s every emotion under the sun,” Hagerich told Fox News Digital. He acknowledged the strong defense presented by his attorneys and expressed gratitude for the prayers and support from friends and strangers worldwide.

During their time awaiting their trails on TCI, Hagerich, Watson and Grier have been supporting each other, forming a close bond as they await their fates and several of them even living together in the same condo.

Several U.S. politicians have responded to the judge’s decision. Democratic Senator Bob Casey from Pennsylvania called the suspended sentence “great news,” praising the leniency shown by TCI authorities. Republican Congressman Guy Reschenthaler also welcomed Hagerich’s imminent release but properly criticized the situation that led to the arrests. He emphasized the need for TCI to ensure the safety of U.S. tourists and indicated he would push for measures to protect Americans.

Reschenthaler suggested drastic actions if TCI does not amend its laws or at least its treatment of Americans, including urging the State Department to issue a no-travel order to the islands, which could severely impact their tourism-dependent economy. He pointed out that 86% of TCI’s tourists are Americans and highlighted the potential economic consequences of such an order.

Senator John Fetterman of Pennsylvania also expressed relief at the judge’s decision, noting the critical role of the U.S. State Department in advocating for Hagerich. Fetterman voiced hope that the other detained Americans would soon be released and reunited with their families.

The arrests of these Americans, all involving stray ammunition from previous trips, have highlighted the strict enforcement of TCI’s firearms and ammunition laws, as well as the concern Americans should have visiting the country.

Reschenthaler’s proposal includes implementing tariffs on U.S. imports to TCI and issuing no-travel orders from states that frequently send tourists to the islands, such as Texas, Florida, and Virginia. He criticized the law as “draconian” and called for immediate changes to prevent similar situations in the future. The country, which depends on U.S. tourists to keep their economy afloat, would feel the pain should such measures be implemented.

A bipartisan congressional delegation visited TCI to discuss the detentions and advocate for the Americans’ release. However, TCI officials have emphasized the need to uphold their legal processes and maintain strict penalties for firearm and ammunition possession to ensure the safety of residents and visitors alike.

The heart of any M1911 is the barrel. Unlike most rifle barrels, this doesn’t just mean the quality of the bore is important — it is. But since the barrel is an integral part of the gun’s cycling, the outside of the barrel is every bit as critical. If the barrel isn’t “fit well,” it won’t return to the same place every time, which means no matter how beautiful the bore is, it will be pointed in a different direction every time the slide cycles. Particularly poor fitting means the gun won’t run at all.

So, when you hear about a match barrel, the important part is less how shiny the bore is as where the fitting points are and how well they are fit to the gun.

“Drop-in” barrels are usually designed to reduce the external tolerances so the barrel fits tighter but don’t usually have all the same fitting points as a traditional match barrel. While it’s an improvement, and may be the only choice for some shooters, it’s not the same as a fully fit barrel.

While everyone does it a little differently, I was taught the “hard fit” technique by Wayne Novak, who learned it from AMU armorer John Miller. Let’s talk about where a barrel should be fit and some basic ways to tell if it’s done correctly.

The fitting points can be summed up in four categories in this order: back, top, bottom and front.

The first part to be fit is usually the hood, which should sit firmly against the breechface (left). Light on either side of the hood is acceptable, as it’s not a critical fitting point. Light between the barrel and the breechface, however, is a bit of a warning sign (right). This pistol will shoot better without the play.

The first part to be fit is usually the hood, which should sit firmly against the breechface (left). Light on either side of the hood is acceptable, as it’s not a critical fitting point. Light between the barrel and the breechface, however, is a bit of a warning sign (right). This pistol will shoot better without the play.

Barrel Hood

The first part of fitting a barrel is getting it into lockup, and this means first filing or stoning the barrel hood that protrudes from the rear of the chamber area. It should begin the fitting process oversize in both width and length.

Generally, this starts with narrowing the sides, then shortening the hood so it will move upward along the breechface. In this step, as with every step, it’s critical to keep the barrel oriented up-and-down correctly so the barrel doesn’t sit at an angle in the gun, and to keep the rear of the hood square to the breechface so it bears on it evenly. There’s a school of thought saying the width of the hood is less important than the length. I tend to agree with this, so it doesn’t particularly bother me to see light on either side of the hood, just not between the end and the breechface. A gun that’s been shot will usually have a print on the breechface showing where the hood moves up and down on it, and a strong, even print is good evidence the hood is fit correctly.

A range rod is a time-honored way to check vertical alignment. The end of the rod will slip into the firing pin hole when the barrel is high enough. This, of course, assumes the hole is correctly located. This rod is from Brownells and has different-sized protrusions on either end for .45 or .38 Super/9mm firing pin holes.

Upper Locking Lug

Once the hood allows the barrel to move upward, the rear upper locking lug — the top of the barrel — is filed until the barrel can move all the way up into full battery, something usually checked with a range rod (a fired, de-primed case is an old trick as well, but won’t work as well with pistols having .38 Super firing pin holes). Often, fitting the top lug includes final fit on the barrel hood as well. The barrel should unlock with light thumb pressure before moving on to the next step.

There’s a misconception fitting the barrel upward into the slide locking lugs is the most important part, so much so some people recommend getting a long barrel link to push the barrel upward, moving the lower barrel lugs upward and away from where they should rest on the slide stop. This is incorrect: While the upper lugs need enough engagement with the slide to adequately lock the breech, an M1911 barrel is most consistently locked in place when the barrel lugs rest equally on the slide stop — hence the importance of a barrel with extra material for fitting on both sets of lugs.

Bottom

Now to the bottom — when the barrel-to-slide lockup has been finished, the barrel is locked into place in the slide and the lower locking lugs are cut through the slide-stop hole while the barrel and slide are installed on the frame. This is another step where it’s critical to make sure the barrel is not locked to one side, which is not good. With the slide-stop “seat” cut into the lugs, the lugs are shaped and smoothed so the barrel and its link will pivot smoothly around the slide-stop cross pin without hitting any high spots left on the lugs.

Looking at the slide stop usually gives the game away about whether a barrel will hit or not: A correctly fit barrel will leave a distinctive wear mark looking like the mirror image of the barrel lugs. The closer the mark is to the full profile of the lugs, the better it will shoot and the longer the fit will last. Uneven or very small marks are less desirable, and flat spots pounded into the cross pin could mean the gun is not unlocking correctly. After cycling the slide by hand, a barrel with good lug support should not move at all when you push down on the chamber area.

Bushing Fit

The front part of the barrel fit consists of how well the bushing fits both in the slide and on the barrel itself, and it’s usually done last (a looser work bushing is used during fitting to keep the barrel aligned in the slide). One of the classic ways of fitting a bushing is to turn the barrel down in diameter about a half-inch or so behind the muzzle, which reduces friction because the bushing doesn’t fully seat until the gun goes into lockup. Match guns may be different, but on a defensive gun, you should be able to turn the bushing in the slide without using a wrench, though you may need to push the slide backward a bit to do it. (Did you remember the bushing fits tightest on the barrel when in full lockup?) Coned or “bull” barrels should also fit tightly at the muzzle, but in this case, the cone is fit contemporaneously with the back and top of the barrel, instead of last like the bushing is.

A correctly fit barrel should show zero discernible motion in the chamber area once locked up, and you should be able to remove the recoil system from the (empty) gun and have it both lock and unlock easily under its own weight when you move the gun from muzzle-up to muzzle-down and back.

If you can do it, congrats, you’ve got a shooter.

Have no fear, The Fixer is here. Faster than a speeding bullet when editing mush, more powerful than a prepositional phrase, able to leap backlogs of pending articles in a single bound, it’s his Editorship, Roy Huntington.

Few people know mild-mannered Special Projects Editor Roy is a superhero of sorts. Sure, you’re familiar with his Super Editor Status when he was editor of American Handgunner and GUNS Magazine, simultaneously at times, mind you. But now that he’s the special projects editor, he has a little more time to hone his other superpowers in between making cool videos and writing feature articles with his turbo-charged Word program.

Working in the confines of his garage and/or machine shop, Roy taps into these other powers, transforming into his alter-ego, “part-time gunsmith guy.”

Roy’s got mills, lathes, drill presses, hammers and files to complete his “gunsmithy” projects. You’ve seen several examples of his work in the pages of Handgunner.

Tank’s Turn

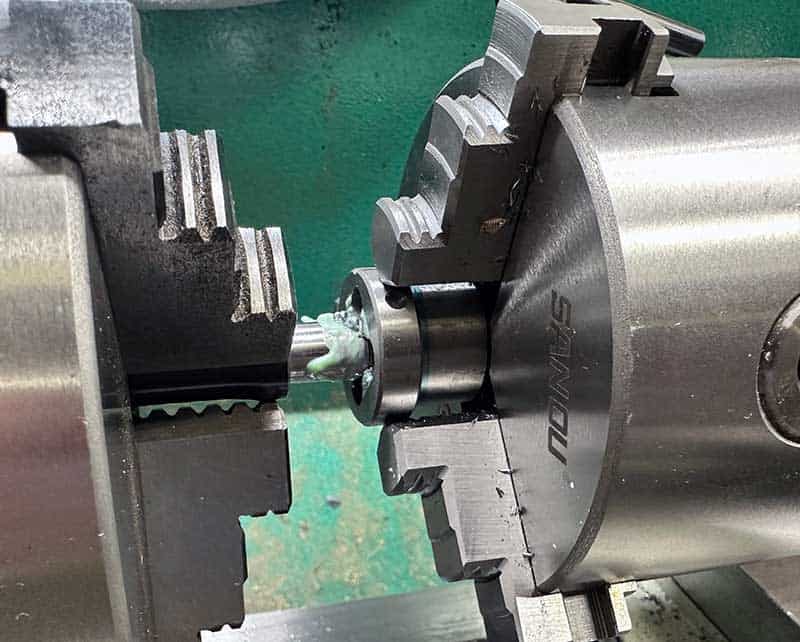

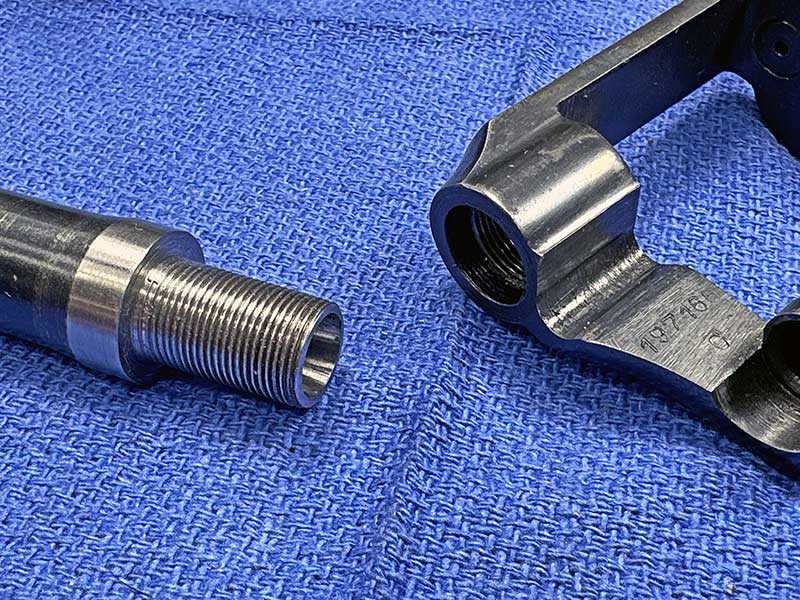

It just so happened I had a project for our superhero. I’d obtained a Colt Police Positive in .32 Colt for a song, but there was a problem. The thin forcing cone was split. I ordered a heavier replacement barrel from eBay, one having a thicker front sight I’d actually be able to see.

But there was another problem. The thread pitch was different than the older barrel. No problemo! Enter — The Fixer. Roy was able to turn down the old threads and re-thread the barrel shank to fit my frame.

When screwing the new barrel on, the front sight didn’t align properly. Rather than turn the shoulder down on the lathe, he used a hammer to peen the shoulder just enough for a snug fit, aligning the front sight so it was perpendicular to the frame.

Then, another problem presented itself. Remember that nice thick front sight? While being easier to see, it was too thick for the grooved fixed “hog trough” rear sight. Roy was able to open it up on the mill, lickity-split.

Care-Free Custom

Now I’m the proud owner of a carefree custom pocket pistol, worked over by none other than Roy Huntington. It looks better with the heavier barrel and has a front sight I can actually see. But more importantly, it was fixed by The Fixer, making my gun more valuable to me because of who repaired it.

The new barreled gun’s thicker front sight nestles perfectly between the freshly cut rear sight notch, providing a wonderful sight picture. I’ll need to figure on a pet load and file the front sight down to correct the point of impact. I’m looking forward to doing it.

I’ve already got some loads and, of course, cast bullets to try out in the re-barreled shooter. I’ll let you know how it goes in another article. But in the meantime, let this be a lesson — it’s always good to know a “Fixer.”

In early November 2000 I had the opportunity to spend about 2½ hours talking with one of the top accuracy gunsmiths in Virginia. I’d taken a rifle I was having trouble with to him to see if he could diagnose the problem. I had a chance to view the inside of my expensive custom barrel through a bore scope. Though I’d only fired about 250 rounds of .270 Winchester handloads through this barrel the throat bore the characteristic look of alligator skin that comes with shooting a barrel when it’s hot.

I was shocked. I thought I’d been quite careful to let the barrel cool between shots, generally allowing at least 8 to 10 minutes between shots. I do recall that on a couple of occasions I did fire as many as five rounds into a group without allowing very much cooling time between shots, but I hardly considered that abusing the barrel.

Generally speaking, I’d tried to follow the old advice to never shoot a barrel if it feels hot to the touch. The gunsmith’s opinion was that by the time you feel heat on the outside, it’s way too hot on the inside.

This revelation started me wondering how many other things I didn’t know about properly caring for rifle barrels. I decided to do some serious research regarding barrel life and the things that affect it. As I researched, I found an enormous amount of material.

Since I’ve mentioned heat I suppose it’s appropriate that I discuss that first. I’m told that the powder charge in high-pressure cartridges burns at a maximum temperature range of roughly 4,900°F to 6,000°F. Barrel steels melt and flow at temperatures of about 2,500°F. The only thing that gives a rifle barrel any appreciable life is the extremely short duration of exposure to such temperatures during each shot, and the opportunity to cool between shots.

In the first few shots from a new barrel, the powder gas probably actually blasts away very thin layers of the surface. Peak temperature of the gas is much higher than the melting temperatures of either chrome-moly or #416 stainless steel. As those first shots are fired, under intense heat and pressure of the powder gases, nitrogen combines chemically with the interior surface layer of the bore to form iron nitrides in the throat and first few inches of the bore. This process is called Nitridation. Under a microscope, this nitrided surface shows up as a white layer. The nitride surface coating in a barrel performs a valuable service in protecting it from the very hot powder gas, but it also is responsible for the eventual loss of dimensions in the throat that we often refer to as erosion.

In the first few shots from a new barrel, the powder gas probably actually blasts away very thin layers of the surface. Peak temperature of the gas is much higher than the melting temperatures of either chrome-moly or #416 stainless steel. As those first shots are fired, under intense heat and pressure of the powder gases, nitrogen combines chemically with the interior surface layer of the bore to form iron nitrides in the throat and first few inches of the bore. This process is called Nitridation. Under a microscope, this nitrided surface shows up as a white layer. The nitride surface coating in a barrel performs a valuable service in protecting it from the very hot powder gas, but it also is responsible for the eventual loss of dimensions in the throat that we often refer to as erosion.

The white nitride is very strong and hard, but it is brittle. The combination of such a stiff coating on the more flexible underlying barrel steel presents problems. Firing one shot hardly makes the barrel feel warm to touch on the outside. However, the innermost molecular layer of the bore probably approaches the temperature of the powder gases for a minute fraction of a second, as each shot is fired. At .0001” into the bore surface, temperature may reach 2800°F. At .001” into the bore surface, the temperature may reach 1000 to 1500°F. Steels which may have a tensile strength of 110,000 to 120,000 p.s.i. at room temperature, show tensile strengths of only 30,000 to 40,000 p.s.i, at 1100°F. The hotter we allow our barrels to get, the more ductile the steel becomes.

As the underlying steel flexes under the pressures produced by firing, the brittle nitrided surface layer becomes cracked. These cracks tend to form “islands” in the nitrided layer. When viewed through a bore scope the cracking presents an appearance often referred to as “alligator skin”, because that’s what it looks like. Over time, thermal and mechanical effects cause chipping of the layer, leaving more sharp edges, cracks and pits, whose edges are then more susceptible to further nitriding. Pits, cavities, and cracks overlap and the result is destruction of the surface, changes in form, and an overall enlargement of the chamber throat.

Now that I’ve given you the bad news, what can you do to minimize heat (and pressure) damage to your rifle’s barrel? The most obvious answer is to allow adequate cooling time between shots. Essentially you want to allow the insideof the barrel to return to ambient temperature before firing the next round. Since damage is directly related to heat and pressure, shooting loads using less powder and producing less pressure should help to some degree. Cast bullet loads using small amounts of fast burning powders at relatively low pressures should allow you to practice a lot with your rifle without causing noticeable damage. If properly done, chrome plating (as currently standard in service rifle bores) can extend accurate barrel life.

What if you always want to shoot full power loads and your bore isn’t chrome plated? Well, actually you’re still in pretty good shape. Jim Carmichel of Outdoor Life magazine set out to see just how long a barrel would last under hard usage. He had a custom rifle chambered in .220 Swift (a notorious barrel burner). He reported that this rifle was initially capable of placing five-shot groups into as little as 3/10ths of an inch at 100 yards. Mr. Carmichel reports using the rifle for prairie dog shooting where he would sometimes fire 40 or 50 rounds as fast as he could aim. He reports occasionally firing 600 to 800 rounds a day if the shooting was really good.

After firing 3000 rounds, Mr. Carmichel carefully examined the barrel with a bore scope and tested accuracy. Though he reports that the area ahead of the chamber showed serious erosion, the rifle still proved capable of ½ inch groups. After 5000 rounds, he reports that the first 2 inches of rifling were literally gone, yet the rifle was still capable of ¾ inch groups. At this point, he reports making one more trip to the prairie dog fields and firing all of his ammunition. Upon his return he tested the rifle for accuracy. The five-shot group exceeded the “magic” 1-inch standard he’d chosen by only 44/1000ths of an inch. Total shots fired through the barrel; 5,920 rounds. Guys, that’s a lot of shooting for most of us. I’d dare say that many of us still wouldn’t be unhappy with five-shot groups that went just over an inch. We might continue shooting that rifle for quite some time.

Other experimenters have reported results with other calibers and rates of fire. I’m told that Highpower competitors using the .308 Winchester cartridge expect to fire approximately 3,000 to 4,000 rounds before replacing their barrels. You’ll note that Highpower competition involves quite a bit of “rapid-fire”. Under “slow-fire” conditions, results can be quite different. The American Rifleman (March, 1956, p. 22) tells of Finnish experiments with a 7.62 mm rifle in which acceptable accuracy for the difficult 300 m target lasted for about 14,000 rounds. The article “Barrel Life” by Q. Kernaghan and B.R. Lewis (The American Rifleman, Feb. 1960, p. 38) cited experiments which showed that grouping ability of .30-06 rifles with Arsenal match ammunition, using the 172-gr. boattail bullet, suffered no decline of accuracy in 8,000-10,000 rounds.

It should be noted that the Finnish ammunition developed a maximum pressure of 39,000 p.s.i., while the 1950’s era U.S. match ammunition produced average pressures of approximately 45,000 p.s.i. These lower pressures no doubt contributed to the extended accurate life of the barrels.

Another factor leading to the relatively long accurate life of the barrels in the above-mentioned tests may have been the bullets used. It has been suggested that one reason accuracy falls off as throat erosion worsens is that bullets are deformed in passing through the eroded area. Some bullets are less subject to deformation and may continue to shoot accurately in spite of serious erosion. Some people have been able to extend the useful life of a barrel by utilizing bullets made with stiffer jackets and core material. Some have also reported improving accuracy in an eroded barrel by using slightly oversize bullets (for example, using bullets of .309 diameter rather than standard .308).

Now that you are aware of the effects of heat on rifle barrel life, you can deal with this factor as you see fit. Even if you literally shoot the rifling out of the barrel, chances are the action and stock are still in good condition. A gunsmith can replace your barrel and you’re good to go again.

As implied (but not stated) thus far, few (if any) rifle barrels wear out from the effects of bullet friction on the rifling. One is then led to ask, “what else shortens barrel life?” According to my research, rusting or corrosion from lack of cleaning is the most common cause of shortened barrel life. Damage from improper cleaning ranks next. (Kind of sounds like the old saw; “You’re D—– if you do and you’re D—– if you don’t.” doesn’t it?) Let’s look a little deeper and see exactly what we’re dealing with.

Corrosion is the disintegration of metal by direct chemical attack or by electrochemical reaction. Atmospheric corrosion is an example of direct chemical attack. Oxygen, carbon dioxide, and water vapor are present everywhere in the air around us. Also present are various corrosive compounds, the more common ones being those containing sulfur and chlorine. Electrochemical reactions occur when metals such as steel and copper having different potentials, are in contact in the presence of a solution which conducts electricity (such as water).

Rusting of rifle barrels does not usually occur unless relative humidity is above 50%. In urban and industrial atmospheres, where large amounts of sulfur dioxide, nitric oxide, or chlorides are present, rusting may occur at as low as 40% relative humidity. In a clean desert atmosphere it may not occur below 70% humidity. However, even with relatively low relative humidity it is possible for condensation to form with diurnal changes in temperatures or, in colder climates, when bringing firearms from the cold into a warm, more humid atmosphere such as a house. With air conditioning in common usage during the hot summer months one must also consider the possibility of condensation when a rifle is taken from the relatively cool indoor environment into the hot, humid outdoors.

High power rifle barrels fired with jacketed bullets and left uncleaned and unoiled, in an average urban atmosphere should be considered prone to electrochemical reaction. This reaction is usually concentrated in cells and patches of rust, instead of a uniform overall rusting.

Rust occupies much more space than the steel from which it is formed. Thus buildups tend to rise above the normal surface of the bore. Rust is quite hard and the buildups will deform and tear loose particles from the bullet jacket, rather than being pushed out or broken up by the bullet. Rusted areas are also prime locations for adsorbed moisture to gather. Even if rust is cleaned away, the metal is usually left pitted; with rough edges, which pick up jacket fouling and ever larger quantities of adsorbed moisture. Once started, rust in a rifle barrel is difficult to clean out and it is very difficult to stop, as it tends to proceed at an accelerating rate.

Rust inside a rifle barrel destroys accuracy. It raises pressures and makes them more erratic. It damages the bullet and upsets its balance. If bullet deformation resulting from a rough and rusted barrel is added to the normal deformation produced by hot, high-pressure powder gases driving the bullet into the lands and down the barrel, accuracy is certain to suffer.

Prevention is simple; thorough cleaning following each day’s shooting, and then application of a light protective coating to the bore. Most common gun cleaning solvents, at best, remove jacket fouling rather slowly. Most high power rifle barrels will show streaks and patches of jacket fouling when examined with a borescope, even when cleaned regularly. If a rifle bore has good interior finish and is of uniform size, a thin gilding metal wash has little effect on grouping. Regular cleaning removes loose powder fouling and partially burned powder particles, thus removing lodging places for moisture. Without moisture, corrosion is unlikely to occur.

Preservative oils which displace water are sometimes referred to as “polarized.” Such oils usually neutralize fingerprints and tend to neutralize airborne corrosive chemicals. They form a water repellant film, sealing over small crevices, cracks, and tool marks to prevent water molecules from coming in contact with the steel. Top shooters and gunsmiths also believe that it’s not good to fire a rifle when the barrel is totally dry. Thus a thin film of gun oil left in the bore between trips to the range serves two purposes. Of course, you’ll want to run a couple of dry patches down the bore to wipe out excess oil before firing as too much oil in a bore can cause serious problems when firing.

A light gun oil is probably not going to suffice to prevent corrosion if you plan to store the rifle away for more than a couple of months. In this case, you’ll want to thoroughly clean the rifle and then apply a grease (such as RIG) or other preservative intended for the purpose.

The forum has previously published an article which I wrote which dealt with what I consider to be proper rifle cleaning techniques. Rather than attempt to rewrite that article here, let me simply state that the most common accidental damage from improper cleaning is probably the uneven “lapping” of various parts of the bore due to using cleaning rods capable of holding grit and using them improperly. You should use a one-piece hardened steel rod (coated or uncoated rods are both OK so long as the coating is non-embedding). Such a rod is unlikely to hold grit, and is resistant to being bent out of shape. Use a rod guide to help direct the rod straight down the center of the bore.

This concludes my thoughts on factors affecting rifle barrel life. I learned a number of interesting things while researching it. I hope you’ve enjoyed the article and perhaps learned something new along the way. It seems that no matter how many years I’ve spent shooting I’m always learning something new. I guess that helps to keep it interesting.