Category: Ammo

The Round That Won The West

You don’t have to play in the AR playground very long before you hear or ask the question; “Does .223 vs. 5.56 matter?” The argument can reach near-religious proportions, with some on both sides vehemently arguing their cases. The deal is this: They do differ, and, yes, it does matter.

The differences really come into play with the starting path of the bullet and the unrifled portion of the chamber ahead of the rifling, called the leade. A narrower (less diameter) leade keeps the bullet from tipping as it moves forward, which enhances accuracy. A larger leade allows for more buildup and gunk and thus greater reliability.

At the end of the leade is the rifling. To prevent bullet mangling, the rifling has an angle on its front face to allow the bullet to slide in and smoothly begin rotating. The steeper this angle (within reason) the more quickly the bullet is controlled by the rifling and thus potentially delivering greater accuracy. However, the steeper the angle, the more the bullet “stalls” on engaging the rifling and the greater the pressure spike.

A shallower angle on the rifling- in effect, a longer ramp- also creates a longer effective leade, as the ogive of the bullet has to travel a greater distance before it engages shallow-angle rifling than it would with steep-angle rifling.

When the .223 was invented, it was meant as a benchrest and varmint round. As such, accuracy was paramount. Velocity was a good thing, but not if it meant losing accuracy. So the .223 was designed with a short leade and steep rifling engagement, which is fine for shooting varmints or targets.

When the Army was forced to adopt the M16, however, it tried to avoid adoption by moving the goalposts, insisting on 500 yard penetration performance. To get that, the designers had to boost pressure and velocity. To control pressure (and also to get full utility out of tracer ammo, which uses bullets nearly twice as long as typical full metal jacket ammo), they modified the shape of the leade and rifling angle. And later, taking advantage of the longer leade and gentler angle, ammo makers tuned the 5.56 round to maximum performance using that extra margin.

Today, the difference can be marked. The leade on a proper 5.56 chamber is twice or more than that of a .223 chamber, and the onset angle of the 5.56 rifling creates a ramp with four times the distance. Firing .223 in a .223 chamber, or a 5.56 chamber, is not a problem. But firing real-deal 5.56 ammo in a .223 chamber can be a big problem.

The SAAMI-spec maximum average pressure for the .223, measured at the middle of the case, is 55,000 psi. The NATO spec for 5.56 is determined by SAAMI’s European counterpart, CIP. CIP measures at the case mouth and lists the 5.56 pressure spec of 62,000 psi. Measured at the case middle as SAAMI does, it shows 60,000 psi- so either way it’s higher than the .223.

But the problem isn’t just pressure. That CIP pressure of 62,000 psi? It is measured in a 5.56 chamber. If we take the same round, which shows 60,000 psi per SAAMI (which is already 5,000 psi over the .223 max) and put it into a .223 chamber, things get ugly. The pressure spike piles onto an already over-pressure round.

I’ve talked to professional ballisticians, guys who use million-dollar labs to measure ammo for their ammo manufacturing bosses. They have reported some instances of 5.56 ammo demonstrating peak pressures at or above 75,000 psi in .223-chambered pressure barrels. That is the pressure of the proof load gun makers test each rifle with before it’s shipped.

Almost all the “generic” ammo you shoot is not 5.56. Oh, it says “.223 Remington/5.56” on it, but it isn’t really 5.56. The high-volume, low-cost ammunition that most of us use is not loaded right to the red line. I’ve chronographed enough of it to know that much of it falls 100 to 200 fps short of full-book 5.56 spec. That right there is enough to make it no big deal because the peak pressure of the .223 load is sufficiently less than that of a true 5.56 that the artificially induced spike still falls below the pressure ceiling.

However, you can have a serious problem if the variables stack up against you in a range session. Rifles get hot when you shoot them. They also get hot in the summer. So on a hot day you’re shooting 5.56-spec ammo through your .223-chambered rifle. The summer sun beats down- note that black rifles left in the sun can easily reach 140 degrees even before they are fired- and pressures rise.

Let’s make it worse: Your 5.56 ammo is at the top of the allowed pressure and at the bottom of the allowed brass hardness. Your rifle suddenly stops working. What happened? The heat increased the already maximum-made-excessive pressure, and on extracting a fired case, the pressure had expanded the case enough for a primer to fall out of the primer pocket and into your rifle.

How can you check for it and solve it? First, you can’t depend on the markings on the barrel. Some makers can be counted on to actually make 5.56 chambers in their barrels. However, many rifle makers do not make their own barrels. They buy barrels, and the barrel makers have been known to ship barrels marked “5.56” that were actually given .223 chambers because .223 chambers tend to be more accurate, and everyone insists on m.o.a. AR-15s these days..

Are there makers you can count on, ones who will supply the proper chamber? Yes. Based on measurements I’ve done over the years, CMMG, Colt, Daniel Defense, LMT, Noveske and Stag deliver chambers that match what’s stamped on the barrel.

Everyone else? Unless you know who makes their barrels, you have to check them, and for that you need a leade/throat gauge. I recommend the .223/5.56 Gage from Michiguns. The gauge is simple. It is ground to just over the minimum specs of a 5.56 leade/throat. Drop it in, and if it drops free, you have a 5.56 leade. If it sticks (it is hardened steel, don’t pound it in) you have a .223 leade.

Okay, so you have a .223 chamber, but you wanted a 5.56. If the rifle is still brand-new, you can send it back. However, the maker probably only has more barrels from the same maker, and you may not get a 5.56. So you need a specialized reamer. One that cuts the leade and the leade only because you don’t want your headspace changed.

The various reamer makers will be happy to supply you with a 5.56-spec finish reamer. You just have to be aware that a finish reamer will also ream the shoulder if you aren’t careful. You may go in attempting to make a 5.56 throat and end up creating excessive headspace. Michigun makes a reamer that does not cut on the shoulder at all. When you feel it stop cutting, you are safely done. It also makes a leade longer even than that of 5.56, by a small margin.

What if you have a chromed barrel and don’t want to cut the chrome? Stick with a chromed .223 chamber. But if you really want a 5.56 leade, yes, the reamer will remove chrome. However, the area being cut is the area where the chrome is blasted off first, so if you’ve put more than a few hundred rounds down your barrel, there is probably not much chrome left there, anyway.

Having a .223 chamber in your AR is a greater concern than just the social ostracism of having a rifle that is not mil-spec. However, it is something you can test and fix if needed. Me, I’m checking all of my rifles, and those that don’t pass the test will get corrected.

What about you? Will you change if your current AR isn’t what you wanted or expected?

According to the Pentagon, the Russian military is running out of ammunition. The problem is so bad, the U.S. military said, that the Kremlin will soon start dipping into stocks of ammunition produced during the Cold War.

This isn’t necessarily a problem as ammunition isn’t perishable. In the right conditions, it can last a long time. The problem is that Russia tends not to store its ammo in ideal conditions that keep it from rotting.

An anonymous source in the U.S. military told reporters on Monday that Russia was running out of new ammunition. “Their stocks of, again, fully serviceable ammunition, you know, this would be new ammunition, is rapidly dwindling,” the unnamed official told reporters. “Which is probably forcing them to increasingly use ammunition in what we would consider degraded conditions.”

The Pentagon said that, at the current rate of use, Russia might run out of “fully serviceable” artillery and rocket ammunition by early 2023. As Moscow continues to burn through ammo in its war with Ukraine, the official said it will have to rely on less safe munitions.

“They have drawn from [Russia’s] aging ammunition stockpile, which does indicate that they are willing to use that older ammunition, some of which was originally produced more than 40 years ago,” the official told reporters.

Moscow isn’t the only country on the planet that uses old ammunition. The U.S. Air Force has repurposed 18,000 40mm shells built during World War II for use in the AC-130. The Pentagon has wanted to retire the AC-130’s 40mm cannons for a while, but they’ve proven too effective.

Properly stored in a climate-controlled environment, ammunition can last a long time. The U.S. Defense Logistics Agency oversees vast stores of munitions left over from America’s various wars. Some of what it’s sitting on is almost 100 years old. Kept in a cool dry place, some of these ammunition might still be usable. An improperly stored round can be volatile, misfire, and even explode, however.

Russia has never done a great job of properly storing its ammo. We know this because their depots tend to explode. In 2020, an ammo storage warehouse southeast of Moscow exploded, taking 75,000 tonnes of ammo with it. In 2019, an ammo storage depot in Siberia exploded. The warehouse was used to store artillery shells, rockets, and various other munitions. A similar explosion injured eight people in 2015, also in Siberia. In 2009, an explosion at an ammo storage warehouse in the city of Ulyanovsk killed two people.

These are just a few of dozens of examples of ammunition exploding in Russia. Ammo depots have exploded in former Soviet countries like Kazakhstan and Uzbekistan. It’s also happened in Ukraine, multiple times.

The use of aged ammo is not necessarily the problem, it’s that Russia could soon be relying on unstable and improperly stored munitions pulled from Soviet-era warehouses that they’re lucky haven’t already exploded.

Shooting my new 8mm Rem mag

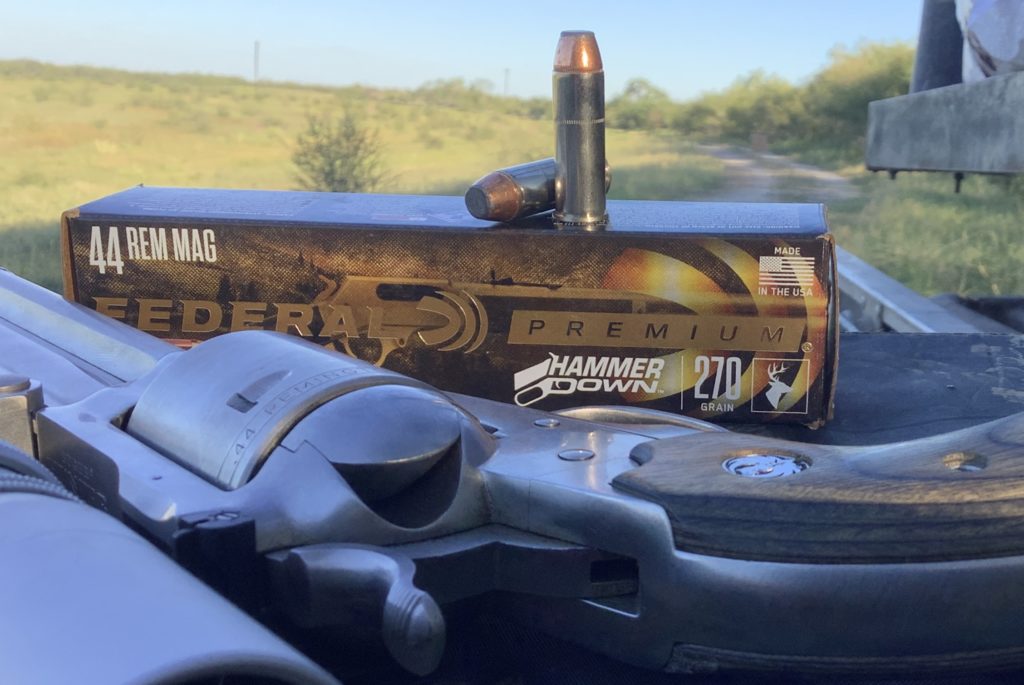

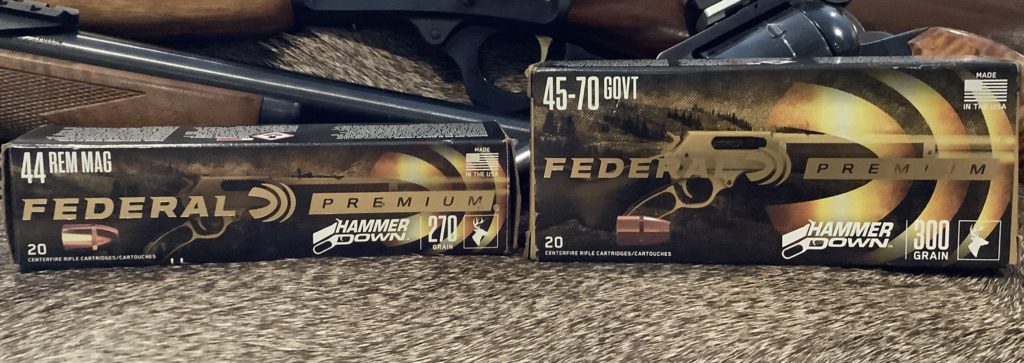

Federal brought out a line of ammunition aimed squarely at levergun users, it’s called HammerDown. They actually produce HammerDown Rifle and Handgun lines, and the bullets used are of the bonded variety which is a welcome upgrade from the standard cup and core offerings. This welcome change should offer deep penetration, ample expansion, and eliminate core separations from occurring. The rifle line is available in 30-30, 45-70, 35 rem., and 444 Marlin, the handgun line has 327 Federal Mag., 357 Mag., 44 Mag., and 45 Colt.

I will be reviewing the 44Mag. and 45-70 rounds. I will test the 44 Mag. in both handguns and a rifle and see how well it does in both as well as compare external ballistics. The 45-70 will be run through my Marlin 1895, 18” barreled semi-custom gun. The 44 Mag will be shot in my Marlin 1894, a 4 5/8” Ruger Super Blackhawk and Ruger Super Blackhawk Hunter. For the 1895, other than the barrel being shortened by a gunsmith, it is a completely stock gun. So all three guns are unmodified as far as accuracy enhancements.

The 44 Mag. ammo uses a 270gr. bullet at a listed 1715fps, the 45-70, uses a 300gr. bullet at a listed 1850fps. Those two performance parameters are awfully close to each other, and although the 44 is listed as being in the handgun line, its velocity is obviously from a longer barrel as it coincides with velocity from my 20” barreled Marlin at 1712fps. The velocity listed for the 45-70 is 1850fps, and from my 18” barreled gun averages 1775fps. It could be that my rifle is a tad slow or that the listed velocity is from a 22” barrel. However, considering the speed of the 44 magnum to the rifle, the two are very close in comparison.

The rounds of the HammerDown line are meant to be used from handguns and lever guns or similar-style guns. They are what would be called today, short-range rounds and luckily most users of these types of guns and rounds are pragmatic and realize that they are best when used at distances less than 200 yards.

My guns are set up for use under those conditions, 200 yards would be a long shot. The 270gr. bullet from my handgun accounted for a large Minnesota doe at 70yds. She covered 60-75 yards in her final dash for cover and left an adequate blood trail for most of the way. The bullet exited after impact and provided about 18”-20” of penetration, it also left a 3/4” to 1” inch exit wound. Velocity from the 7.5” revolver averaged 1350fps, and given the 2.5” high impact at 50 yards provides a very useable trajectory for hunting purposes.

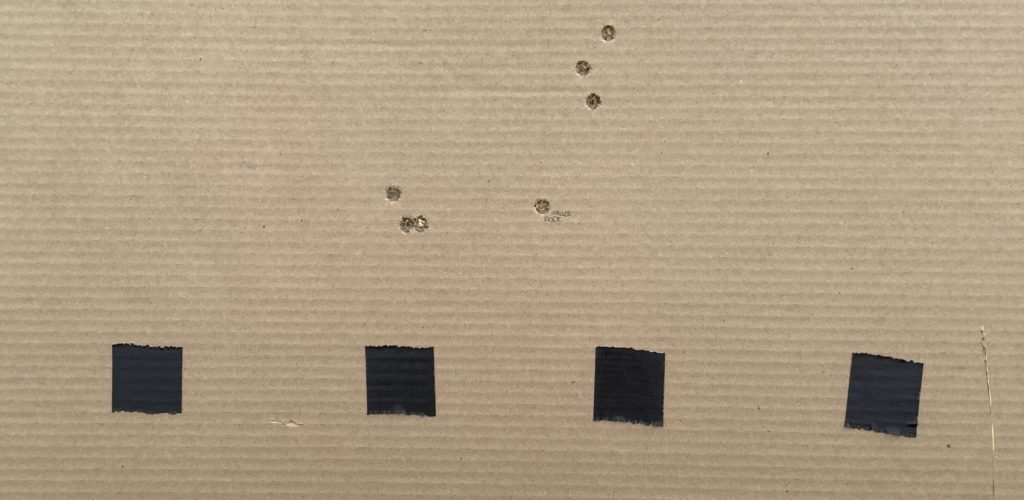

The shorter barreled Ruger provided 1270fps with the load and gave 2” accuracy at 50 yards at 1.5” high. The Marlin 1895 is outfitted with a Burris FastFire reflex sight and is sighted to place its rounds just over the top of the dot at 50 yards, this works out to just over a 100-yard zero. The initial shooting of the ammunition provided some quite acceptable accuracy, with the rifle producing just over an inch group at 100 yards for the first three rounds fired from it. The handguns produced the same 2-inch groups at 50 yards with their first rounds.

The 45-70 ammunition also produced very acceptable accuracy with its first rounds fired, two rounds fired produced about an inch coupling at 100 yards but a bit higher than I prefer. So a couple of clicks down and three more rounds produced a 1.75” group.

The zero I prefer to run on my 45-70 consists of 2.5” high at 50yds, 3” high at 100yds, and zero at 150yds, should a shot at 200 yards be needed simply aiming at the top of the back compensates for the 9” drop on whitetails and just below the top of the back works for the bigger stuff. This makes for easy remembering while in the field and 2.5” to 3” of height equates to nothing really when aiming at deer, hogs, bear, or elk.

The function of both 44 and 45-70 through the lever guns hasn’t met any issue, which is what I expected. In the past, some have reported issues of sporadic feeding problems with other manufacturers ammunition using bullets of wider meplat in their Marlins. I did not have any, but the HammerDown ammunition is developed to function through a lever action. The flat nose profile of the HammerDown 270gr. bullet is wider than many factory-loaded jacketed bullets, with my caliper it measured out at .290, in comparison, Winchester Silvertip measured .225, Hornady XTP measured .275, and Sierra measured .250, I found only one load that exceeded it and it measured .295. The two loadings utilized nickel-plated cases, making identification of ammunition easier when mixed amongst normal brass casings, and when looking for spent cases in the grass.

The 45-70 bullet is called a soft point, although it resembles a cupped point, not a soft point and not a hollow point, but a blend of the two. Regardless of what it’s called, it performs like what you would expect from a bonded bullet, with no core separation and excellent expansion. My experience with a different 300gr. bullet in the 45-70 started out with less than stellar performance, and consequently, I’ve steered away from using them.

The bullets used were designed for much older 45-70 loadings, ones meant for trapdoors and weak actions. Luckily these days we have loadings designed for what is currently 45-70 ballistics from modern strong actions. The other 300gr. bullet provided limited penetration when pushed at 1800-2000fps so I decided to go to a tougher bullet, one also made by an ATK company, the Speer 350gr. SP. This HammerDown 45-70 ammunition would be the first time I’ve shot anything less than that 350gr. bullet since I switched.

In looking at the jacket thickness of the sectioned bullets, it is obvious that the 45-70 bullet is considerably thicker than the 44 bullet. Considering that both are moving at about the same speed from the rifles, makes me think the 45-70 bullet should be a great penetrator, which is what I look for from a large caliber projectile. Some expansion is good, but too much hampers penetration. The penetration provided by the 44 bullet when fired from the handgun at 1315fps, was excellent on the big doe. The question is how will it do with an extra 400fps when fired from the rifle and on a bigger tougher animal?

The search for a bigger and tougher target began in south Texas, looking for a big pig. The first game to fall to my 45-70 was an eighty-poundish feral hog sow. She and her herd were rooting up an area around a small pond or tank as we call them in Texas. It was just past 6 pm and the rules on this ranch stated no shots allowed after the legal shooting light, so even though feral hogs can legally be shot at night, not so on this ranch. Luckily, we found the herd in time and spotted them with the setting sun behind us, because we were 150 yards from them when we spotted them.

I crept forward another 50 yards and took a knee, got a solid hold on the sow, and sent a 300gr. HammerDown at her. Since I didn’t want to go looking for her, I aimed for a high shoulder impact. The bullet landed true to the sights and she rolled over in the classic stiff-legged immobility posture so often seen with a severed spine shot. Even though her chest was only about 12” wide, bullet expansion was evident from the exit wound through the offside shoulder. Due to her size, she was a perfect candidate for donation to a family in need of protein.

Our next target was a tad bigger and much smellier. As males get bigger and start roaming they become solitary and get a smell that is pungent and unique. Typically if a large pig is found by itself it will be a male and bigger than the ones found in a herd. On the south Texas ranches that I frequent, a big male will be 200+ pounds and occasionally you’ll find a 275 to 285-pounder, though those are truly big pigs for the region. Every once in a while one bigger than that will turn up, but our natural vegetation doesn’t really support great big pigs.

The ranch has some big old live oak trees and grassy plains, the pigs like to root around looking for acorns, but tear up the grassy plains where the cattle graze. This causes big and sometimes deep holes that cattle can stumble in and break a leg, can’t have that!!

The one that I found weighed right at 198 pounds on the hoof, but he was thick enough to catch and stop the 300gr. bullet. I purposely waited for him to turn to quarter so I could run the bullet through as much pig as possible. The bullet caught him at 115 yards and landed behind his last rib and traveled through the vitals, broke 2 ribs on the offside, as well as the shoulder, and lodged just under the skin. Total penetration was about 24 to 26 inches, he made it about 75 yards before expiring. I find this normal for a hard-hit pig that isn’t spined or brained.

Had I not been intentionally trying to stop the bullet, I would have spined it or taken it broadside to ensure an exit. Running 75 yards into thick brush without an exit to provide an almost immediate blood trail can lead to a lost animal. Knowing I had nothing but grassy plains and could keep my target in view while it ran allowed me to not be concerned about finding it.

After finding the pig I decided to test the 44mag 270gr. HammerDown bullet on it from the Marlin. Since the rifle produced an additional 400fps with the load, I was curious how the additional speed would affect penetration. Shooting the pig broadside through the shoulder from 60 yards allowed almost complete penetration. The bullet went through one shoulder and its shield, broke 2 ribs going in and two ribs coming out, it penetrated the scapula and lodged in the shield of the offside skin. Considering the additional velocity the rifle provided this is excellent performance and I’d speculate that from a handgun the bullet would completely penetrate on a broadside shot.

As is normal for my reviews, here is my biggest, most, and least list. The biggest surprise was the similarity in velocities from the 44mag and 45-70 when fired from similar rifles, both bullets perform extremely well.

The biggest disappointment is actually a case of our current merchandising conditions rather than an actual product issue, that is product availability. It’s a shame because this product is a great performer and should be well-received by the shooting public.

The least liked feature is one I’ve mentioned before on other manufacturers’ products and it’s their product packaging. This applies mostly to the handgun cartridges because sighting in and verifying trajectory at 25, 50, and 75 or even 100 yards eats up most of your ammunition.

The most liked feature is the bonding process that is used on the bullets,….it works. I inadvertently tested it in the extreme. When I used the big pig carcass to stop bullets for picture purposes I accidentally ran two of them into each other. Yet both bullets never lost or shed jackets or even slightly separated core from their jackets. A true test of the bullet’s ability to retain integrity and penetrate well.

Federal lists these two loads as being designed for medium game. I would say they are well-designed for all game up to 300 pounds, although after using them I would not hesitate to use them on say cow elk or red stag. Something a little heavier but still thin-skinned and light-boned. Accuracy has proven to be excellent, and performance is stellar, if you own a 45-70 or 44 magnum and need ammunition for hunting game, look no further than Federal HammerDown.