The M1 Garand that served the U.S. military from 1936 through 1958 is made up of 57 parts. While every one of those parts is critical to the operation of the rifle, some are more important than others, like the barrel, bolt and receiver.

The gas cylinder is central to the M1’s semi-automatic operation and, of all the parts on the rifle, it is the one that experienced the greatest amount of change over the Garand’s development and production history. In fact, when John Garand began developing a gas-operated semi-automatic rifle in June 1926, he went with a basic gas cylinder design that would eventually evolve through a series of changes – some significant and some not – that singularly and uniquely narrate the entire M1 story from development to mass production.

Through the evolution of that one part, it is possible to see the many ways that a brilliant engineer overcame technical and production challenges that would have thwarted a lesser mind.

Foundation of Success

After abandoning primer actuation, the first thing that John Garand did was design a gas operated rifle in .30-caliber, and that rifle received the designation T1. The Army examined the T1 in December 1927, but expressed more interest in the design than the caliber. John Pedersen’s .276 cartridge was at the time thought to be a better candidate for a semi-automatic service rifle than the more powerful .30-caliber cartridge, so Garand was asked to create a version of his gas-operated design in that caliber. He then modified the existing design for the .276 cartridge. The result was designated T3 in 1929.

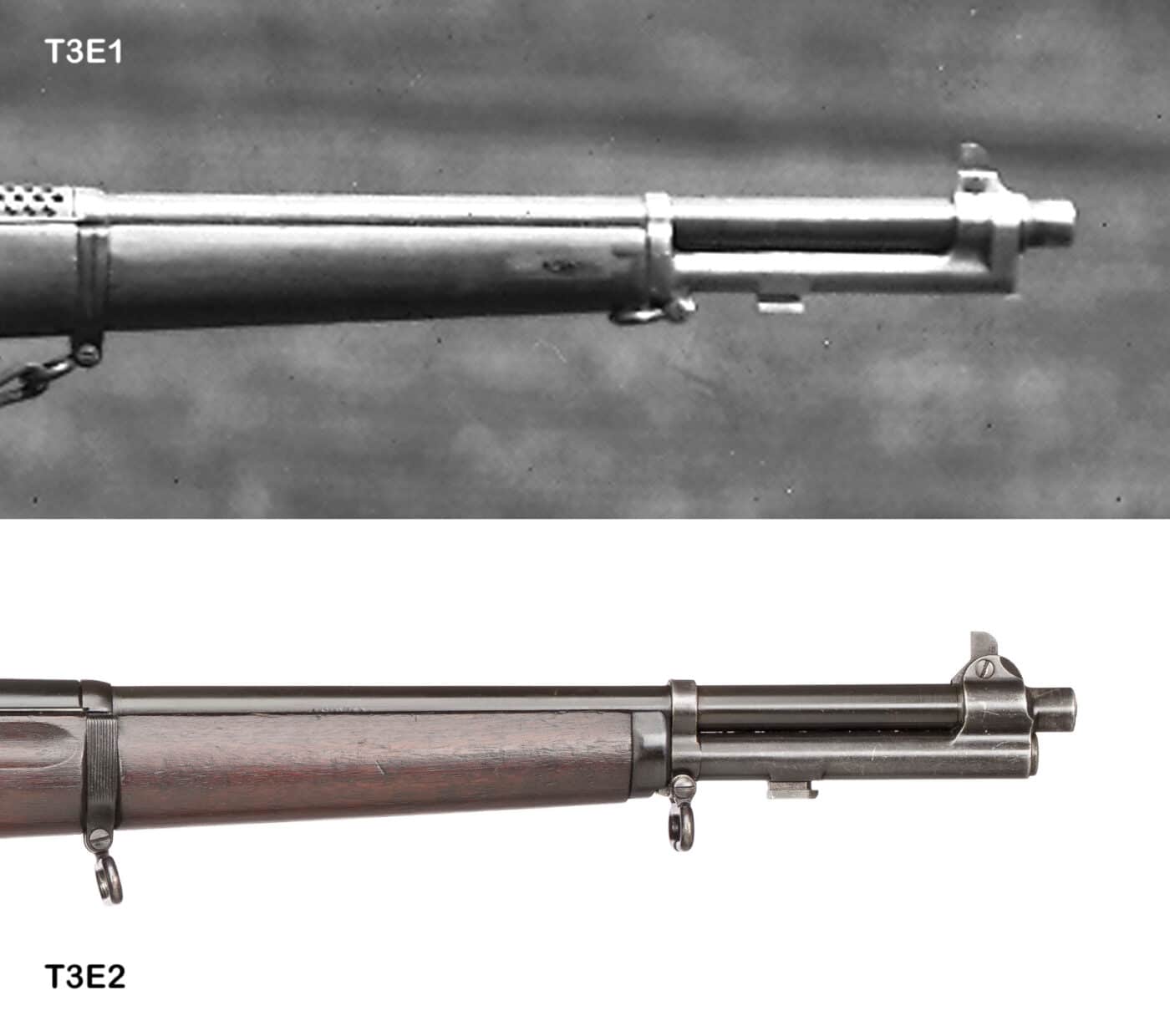

At this critical stage of development, John Garand’s gas cylinder went through some interesting, although primarily cosmetic changes. All of the rifles were “gas trap” type rifles that used gas pressure at the muzzle to the operate the action. Since that aspect of the design did not change, the basic anatomy of the rifle’s gas cylinder did not undergo fundamental modification the way that the M1’s gas cylinder ultimately would in 1940 (more on that below).

A noticeable change to the appearance of the gas cylinder between the T3E1 and the T3E2 did however take place. The rear end of the T3E1 gas cylinder also served as the forward stock ferrule, but Garand simplified that when he transitioned to the T3E2 by separating the components from one another. He further simplified the E2’s gas cylinder by eliminating machining cuts in the area of the gas trap, and by making the front sight base a curved structure.

Bigger Might Be Better

In 1929, the military showed a renewed interest in a .30-caliber Garand rifle, and that paved the way for the short-lived T1E1. But when that rifle’s bolt developed a crack during testing, it was subsequently withdrawn from trials on October 9, 1931. Four months later, U.S. Army Chief of Staff General Douglas MacArthur halted further development of the T3E2 Garand and the .276 cartridge, and ordered all resources dedicated to correcting the problems with the .30-caliber T1E1.

By then, John Garand had made a new bolt for the rifle and completed a few other adjustments to its design. This modified version received the designation T1E2 in March 1932, and it was this version of the Garand that was ultimately adopted as the “U.S. RIFLE CAL. 30 M1” on August 3, 1933.

But the first batch of 80 M1 rifles was handmade at Springfield Armory’s Model Shop between April and August 1934, and they were built with a gas cylinder resembling the T3E2’s. While both made use of an unprotected front sight blade, the gas cylinder design equipping the 80 pre-production “Model Shop” M1s included a feature that the T3E2’s gas cylinder did not: a removable nose cap that allowed cleaning of the interior of the gas trap’s expansion chamber. So even at this early stage in the life of the M1 Garand, the design of the rifle’s gas cylinder was already going through product improvement.

Mass production of the M1 rifle began in July 1937 with serial number 81, a rifle that introduced a slightly revised gas cylinder. In recognition of the fact that an unprotected front sight blade was just not a desirable feature for a service rifle, the curved front sight base used on the gas cylinder of the “Model Shop” rifles was replaced with a squared-off base. A milled front sight with protective ears fit in that base and gave the “gas trap” M1s something sufficiently rugged for military service. The improved gas cylinder was assigned drawing number D-28289 and it would remain largely unchanged during the next 35 months of production.

Nevertheless, three separate variations of that part were made that can be identified based on the presence or absence of the drawing number on the rear barrel ring, and/or a pair of flutes machined just below the rear sight. Production of the “gas trap” M1s proceeded through to mid-1940 when the rifle’s design underwent a major change.

Field Feedback

By 1939, extensive field use of the M1 had revealed a number of shortcomings associated with its gas cylinder. First of all, it was possible for the screw securing the part to the barrel to loosen while firing, and this could cause a misalignment that could cause a bullet strike that would damage the gas system irreparably. In addition to that, it was difficult to clean excessive carbon build-up in the gas cylinder, and that could affect reliability.

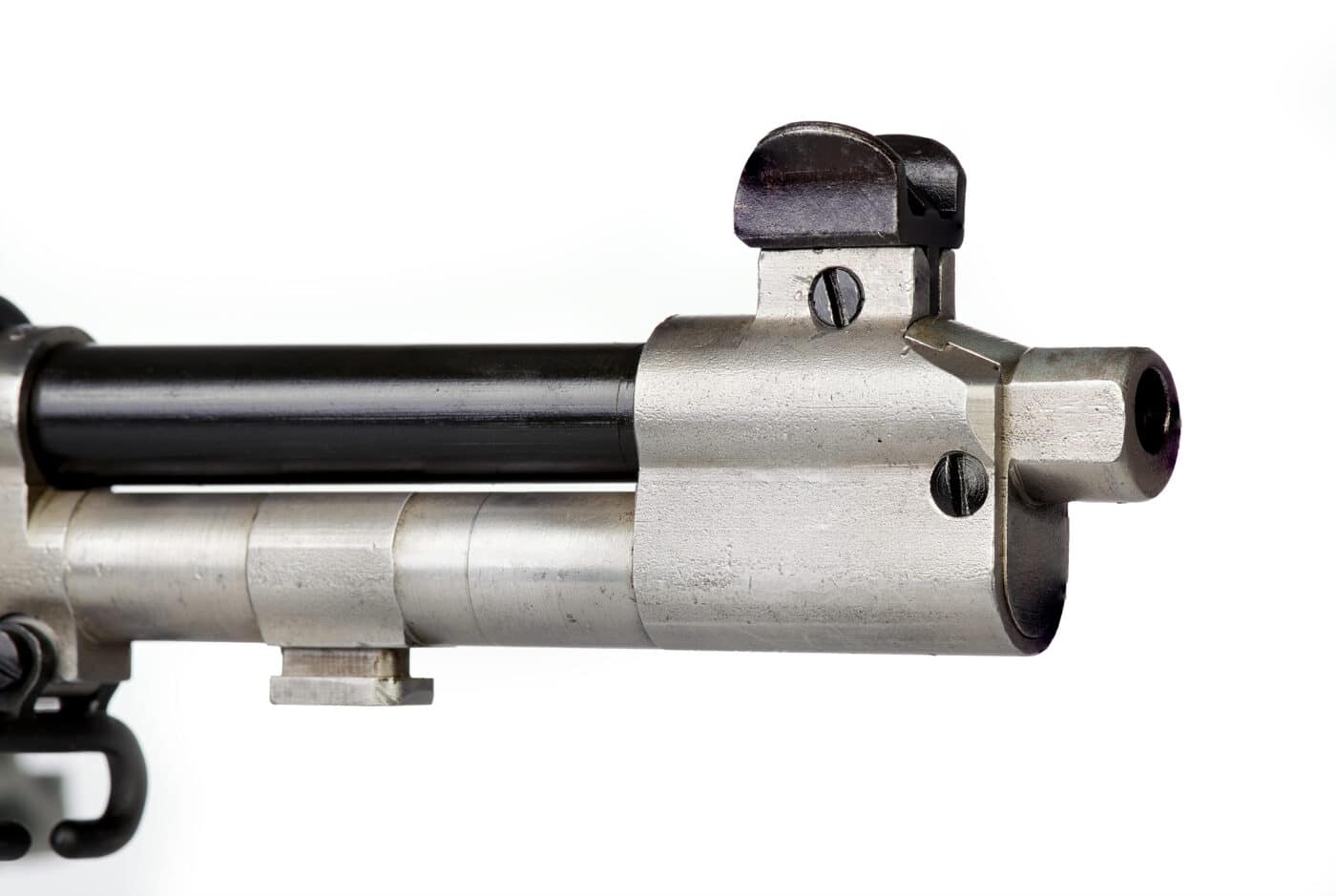

Garand cured the problem by converting the rifle from a gas trap to a gas port operating system. This involved lengthening the rifle’s barrel from 22” to 24”, and then drilling a .078” diameter port in it that lined-up with a corresponding window in a heavily modified gas cylinder. Gas pressure still put the rifle into an operating cycle, but that cycle was now initiated at the gas port instead of in the expansion chamber at the muzzle.

The new gas cylinder was assigned the drawing number D-35449 and it was recommended for adoption on Oct. 26, 1939. At that point, 48,119 “gas trap” M1 rifles had been produced, but from mid-1940 through to the end of production in 1957 every Garand was built as a gas port rifle with a D-35449 gas cylinder.

Although minor variations can be identified, the Garand gas cylinder had reached its final form with D-35449 and its simplicity reveals another noteworthy attribute of the M1 design – the ability to evolve. Just by examining the way that one part changed between 1926 and 1940, it is possible to understand how a good service rifle ultimately became the greatest service rifle of the 20th century.