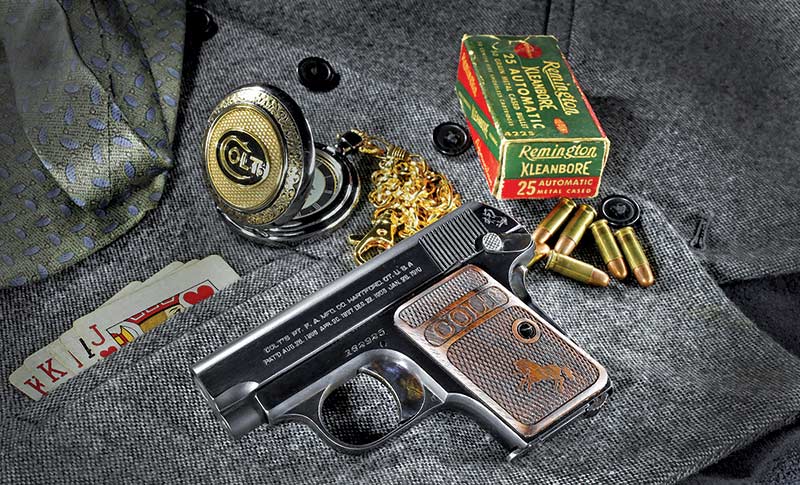

Some of the best things in life are small. Take the Colt “Vest Pocket” 1908 auto. A very small pocket pistol built at the turn of the last century designed by John Browning, chambered in .25 caliber — which he also designed. This example is from 1917. The owner picked it up at a very reasonable price, but it needed full refinishing.

First, I disassembled the pistol to evaluate all the parts. Next, what was left of the bluing was stripped with muriatic acid. The slide and frame were repolished, like the original factory finish. Some scratches were deep enough they could not be removed without loss of the roll marks.

The Colt “Rampant Stallion” logo needed to be re-engraved, so it went to Brian Powley, a master engraver. Small parts that had once been color-case hardened were stripped and sent to Tyler Gun Works in Texas for a new color-case finish.

The barrel was lapped with JB Bore compound to remove some minor frosting. Eagle Grips replaced the original broken celluloid grips with wood matching the factory design. My son Nick blued the frame and slide while I cleaned up all the internals. For a little bit more color and style, Nick nitre blued the pins and screws. There are not too many parts — making assembly easy. Wolff offers new springs, which were needed. The little pistol shoots great. It’s a little small for big hands to activate the grip safety but makes a great out-to-dinner pistol for the pocket or purse.

If the Shoe Fits — Trigger Shoe That Is

For years, some shooters have struggled with the Colt National Match and later Gold Cup pistol models with the “wide” target trigger. The trigger was unique to the two models and so limited that few after-market options are available. My dad shot the Colt National Match in NRA Bullseye matches. His trigger was modified to fit a short finger by cutting it in half, removing some length and soldering it back together.

Evolution Gun Works (EGW) offers a “blank” wide aluminum trigger that needs machining from its block form. Now along comes Ned Christiansen, a mad genius in his own right for one-off pistol creations. Ned designed an aluminum Gold Cup trigger that fits the frame’s wide trigger track but ends up being the standard 1911 trigger width. It is also oversized to allow the shooter or pistolsmith enough material to get a snug fit with little or no vertical play. The trigger is offered by EGW under license from Ned.

Crowning Achievement

Hardly a day goes by that someone asks about a “reverse barrel crown.” I just think of them as crowns. The crown has gone from protecting the terminal rifling from damage to more of a fashion statement today. Most manufacturers apply a small crown to the barrel muzzle in the order of 11 degrees as a finishing touch. Today custom gun owners want pretty heavy bevels up to 45 degrees. I like to make them at 35 degrees, a compromise deep but not megaphone deep.

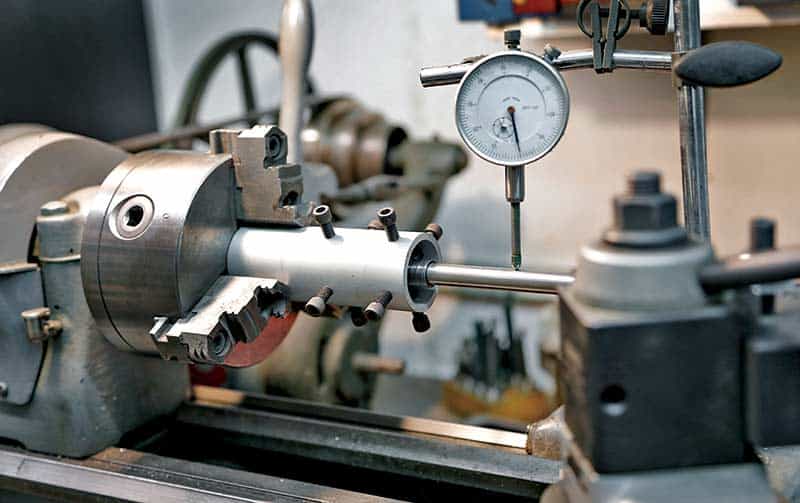

To make the crown, I turn the barrel on a lathe, making sure the inside of the barrel is turning true. If the crown is not concentric to the bore, it looks terrible. For precise milling, I use a “spider” jig, a tube with eight screws holding the barrel, allowing it to be adjusted to turn true to the bore’s axis.

It takes a bit of time to tune in a barrel at first, but it gets easier with practice. I use a mandrel made for the bore, which allows me to dial indicate the barrel. Once dialed in, I remove the mandrel and use a small cutter to remove material from the center of the barrel and make a new crown. The final pass is very light to remove tool marks. Some light sanding with crocus cloth removes any burrs and brightens the crown. As for accuracy, I have not seen any difference after deep crowning. I think the accuracy is a result of the clean cut of the crown.

The muzzle end and crown are a major focal point of any gun; it’s important to take the time to get it right.