The SIG Sauer P365 Fuse represents a groundbreaking fusion of micro-compact concealability and full-size performance in a single handgun. This innovative pistol bridges the gap between easily concealed carry guns and high-capacity, full-featured firearms.

The P365 Fuse features an optic-ready slide, allowing users to mount their preferred red dot sight for enhanced target acquisition. Despite its compact footprint, the pistol boasts a 4.3″ carbon steel barrel with a durable DLC finish, providing excellent accuracy and longevity.

The stainless steel slide incorporates aggressive serrations for improved manipulation, while the polymer LXG grip module features a laser-engraved texture for enhanced control. In addition, the grip module includes a 1913 accessory rail for mounting lights or lasers and a removable mag well for faster reloads.

Customization is a key aspect of the P365 Fuse, with interchangeable small, medium, and large backstraps included to ensure a perfect fit for various hand sizes. The nickel-plated, flat-faced trigger offers a crisp break and short reset for improved shooting performance.

Sighting options include a fiber-optic front sight paired with a black serrated rear sight, providing a clear sight picture in various lighting conditions. The slide is ready to accept popular red dot sights for those who prefer optics.

The P365 Fuse has impressive magazine capacity, shipping with two 21-round and one 17-round steel magazine. Bolstering high capacity, combined with its compact size, makes it an excellent choice for both concealed carry and home defense.

As a bonus, the P365 Fuse comes holstered in the Photon Holster by Alien Gear Holsters, ensuring users have a quality carry option right out of the box.

The SIG Sauer P365 Fuse truly delivers on its promise of combining micro-compact concealability with full-size performance and capability, making it a versatile option for shooters seeking a do-it-all pistol.

This all started typically for me. I walked into a gun store on University Avenue in San Diego about 1980 and there, staring at me from the display case, was a “sorta’ rusty” Second Series Colt Woodsman, which “mostly worked” according to the counter guy. In those pre-internet days his “Colt” book showed it to have been made in the 1949 to 1950 time frame. For a “Hunnert bucks” I owned it.

I had been hankering after a real Colt Woodsman for a long time but most were outside of my pay grade. Sure, Ruger Standard .22 Autos likely did the same job, but they didn’t have the elegant lines of the fabled Woodsman. Besides, all my old Gun Digest books had old guys wearing fedoras taking aim with those early slender Woodsman autos and it all seemed very mysterious. They looked like they knew something I wasn’t privy to. But now I’d find out, wouldn’t I?

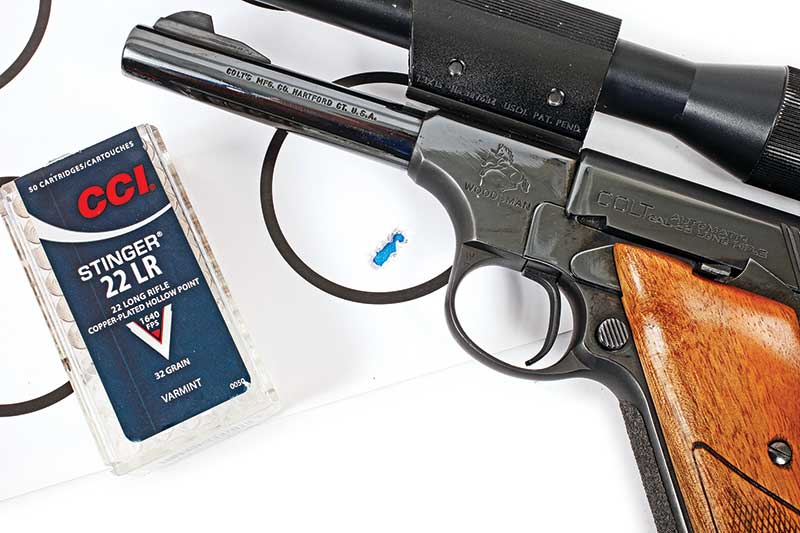

Thanks to Numrich Arms, I soon had a new firing pin and found the Colt shot just fine. The rifling was clean and sharp and it seemed to run well. Accuracy was also excellent with my then-young eyes. But the light pitting and patina just didn’t set right to me so after much slow work with wet-or-dry paper and even a fine file at times, it was looking pretty good in the white. A local gunshop handled a re-blue — $49 since I had done all the hard work — and the result is what you see in the pics. While not that lovely early Colt blue, it got the job done and I had a “real” Woodsman. While not as rakish as the early ones having the pencil barrel, it was still fun to own and shoot.

Years Passed

Around 1986 the Colt was on my work bench and by an odd coincidence, so was a very early Bushnell Phantom scope. That was the 1.5 power scope which, when you looked through it, always seemed to make the target seem smaller than real life. I once had an optics engineer explain it to me but it still didn’t make any sense, so I just nodded like I was understanding him, then trundled off still confused. I still don’t understand how a 1.5x “magnification” makes things smaller.

Nonetheless, smaller or not, I started to eyeball that scope, then the Colt sitting nearby, then the scope, then the Colt — this going on for some time. I even held the scope up to the top of the gun and it sorta’ looked right. I dug into my “scope bits” box and found a rail from an early TC Contender which the scope’s integral mount would fit on.

Then I eyed my bench-top milling machine — and an idea was born.

“Bein’ since” — as they say here in Missouri — this wasn’t a collectible Colt I figured installing the scope on it wouldn’t hurt a thing and just might be pretty darn fun to boot. With no small amount of eye-balling involved, some breath-holding while I drilled into the top of the Colt and one broken tap as I recall, it went together. Much to my surprise and delight, the cross-hairs were even straight. That was a good thing as the scope can’t be rotated in the mount.

Did it work? In spades, as they say.

I shot a zillion rounds out of this combo and it chased no-end of Southern California jack rabbits, Necco Wafer targets (remember those?) and counted plinking adventures in the thousands. I remember at the time being able to keep pretty much ragged, one-hole groups at 25 yards with the right ammo. It was a deadly combo and I’ve never seen one like it since. Today, it’s easy to scope a .22 pistol, and my S&W Victory .22 in the picture is sort of a modern version of what I did 33 years ago — but the Woodsman still rocks, if you ask me.

When I saw it in my safe not long ago I dug it out and put it to work. It’d been years since I had shot it last. I found it was glitchy though, failing to engage the sear sometimes, and even doubling now and again. Hmmm …

I dug into it and guessed the sear spring had taken a set or weakened some — hey, 70 years is a long time — so tuned it up a bit, re-shaping and re-tempering it. After the install, all ran just fine again. I went ahead and put in a new hammer spring and recoil spring while I was at it too. A good lesson here if your Woodsman is doing the same thing — it’s likely the sear spring is not engaging the sear reliably.

My target shooting afterward revealed the old girl still shoots. That ragged one hole, 5-shot group at 25 yards was done with CCI Stinger ammo, of all things! It was the best at that range. One group with CCI Mini-Mag HP at 40 yards measured about 1.25″. Nothing went over 1″ at 25 yards. I don’t care who you are, that sort of performance out of a 70-year-old gun with a 50-year-old scope and 65-year-old trigger-man is amazing — and great fun. If all this sounds interesting, dig up a beater Ruger Standard Auto, or old Browning Buckmark .22 and go to work. Let me know how it goes if you do it.

A Winchester Model 71 .348 WCF