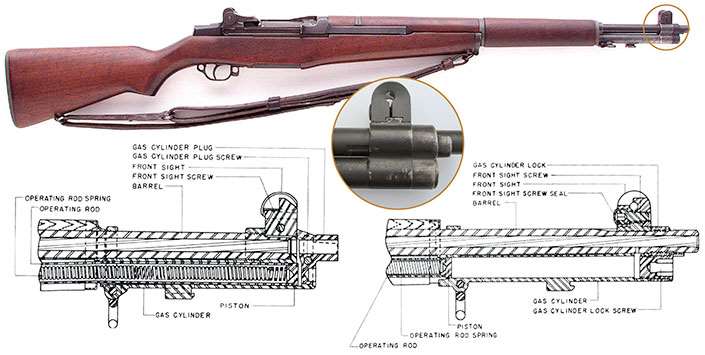

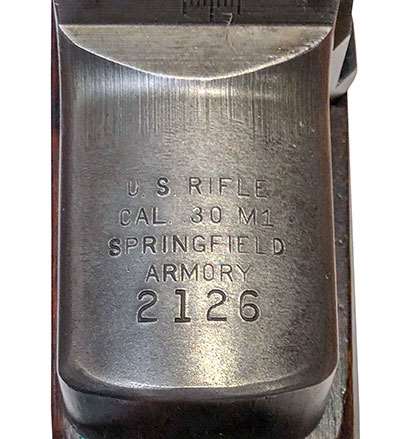

One of the most famous and respected U.S. military service rifles of all time is the “U.S. Rifle, Caliber .30, M1,” popularly known as the M1 Garand in recognition of its inventor, John C. Garand. The rifle is well-known due its widespread use in World War II and Korea, as well as its popularity with many present-day collectors and shooters.

What is not so widely known, however, is that the rifle as originally adopted in 1936 and manufactured for the first four years was markedly different in one aspect from the version so well-regarded today.

The genesis of the M1 began shortly after World War I in 1919, when John Garand was hired to work at Springfield Armory on the development of a semi-automatic rifle. Even before Garand was employed, a number of domestic and foreign semi-automatic rifle designs had been evaluated at Springfield, but none had proven to be satisfactory.

One of the more promising designs was the Danish Bang rifle, which featured a “muzzle cap” that trapped the escaping gas after it exited the muzzle and utilized it to operate the rifle’s action. First tested in 1911, several variations of the Bang rifle were evaluated at Springfield as late as 1928.

After some experimentation, including an unusual primer-actuated design, John Garand settled on a gas-operated mechanism for his rifle. Although the Bang rifle had not proven to be satisfactory overall, Garand undoubtedly was influenced to some degree by the rifle’s gas system.

His gas-operated T1 prototype rifle was chambered for the standard .30 Springfield (.30-’06 Sprg.) cartridge, but Garand was directed by Ordnance to scale down the rifle to a .276-cal. cartridge championed by John Pedersen, who also had a semi-automatic rifle in parallel development at Springfield Armory during that time.

Designated as the T3E2, Garand’s .276-cal. rifle subsequently edged out the Pedersen design and was recommended for adoption. Nonetheless, for several reasons, the War Dept. disapproved of the .276 cartridge and mandated the rifle instead be chambered for the .30-cal. cartridge, which had been John Garand’s preference all along.

In 1934, 80 such .30-cal. rifles, designated as the T1E2, were fabricated in Springfield Armory’s Model Shop and thoroughly tested with very good results at several Ordnance facilities.

The rifle was adopted on Jan. 9, 1936, as the “U.S. Rifle, Semiautomatic, Caliber .30 M1.” “Semiautomatic” was soon dropped from the nomenclature as there was no need to denote the type of mechanism.

A signature feature of the new M1 was its Bang-influenced gas system, which has been dubbed by collectors today as the “gas trap” in recognition of the manner by which the escaping gas was collected.

The front sight on early-production rifles had straight protective ears, but it was found that inexperienced shooters sometimes mistook one of the ears for the sight blade—which was obviously deleterious to accuracy. The problem was soon corrected by making the ears flared so they were easily distinguishable from the front sight blade.

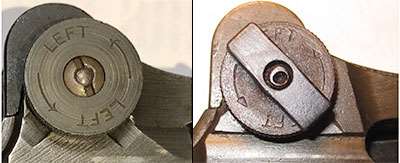

The rear sight was one of the best ever used on a military service rifle, before or since. It had a peep aperture and was easily adjustable for windage and elevation. The windage knob was secured to the pinion by a spanner nut.

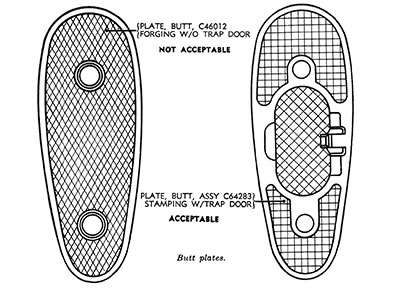

A feature unique to the “gas trap” rifles was a metal “lip-type” ferrule that separated the front handguard from the gas cylinder. These rifles also utilized an operating rod spring and separate compensating spring that were of the keystone (square wire) configuration. As originally adopted, the M1’s stock did not have a recess in the butt for storage of cleaning implements, etc., and used a one-piece solid buttplate.

When inspection of a rifle was successfully completed after manufacture, a Final Inspection Stamp, often colloquially termed a “cartouche” by collectors today, was impressed into the left side of the stock. The stamp consisted of “SA/SPG.” “SA” indicated manufacture by Springfield Armory and “SPG” represented the initials of Chief of Small Arms Inspection Stanley P. Gibbs, who was a civilian employee at Springfield. All of the “gas trap” M1 rifles bare Gibbs’ inspection stamp.

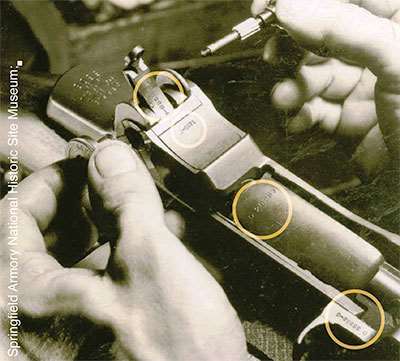

Another interesting feature of the gas trap M1s was the presence of “Drawing Numbers” on most components consisting of a letter prefix (“A” through “F”) that denoted the size of the component and a number that identified the specific part. As many of the parts were subsequently changed for better performance or easier manufacture, a “revision number” was added.

For example, the initial Drawing Number of the rear sight aperture was “B-8868,” and with the first revision of the component it was changed to “B-8868-1.” The Ordnance Dept. eventually came to the conclusion that the marking of so many parts wasn’t worth the effort, and, as production continued, fewer and fewer parts had Drawing Numbers applied.

Eventually, only the major components, such as the receiver, barrel, operating rod, bolt and trigger housing were marked with Drawing Numbers.

While many small nagging glitches cropped up and were solved one-by-one during the initial course of production, a major problem occurred when it was found that many of the new rifles jammed on the seventh shot.

Finding the cause of the so-called “seventh round stoppage” resulted in Springfield Armory engineers having to burn the midnight oil. It was eventually determined to be a slight deviation in John Garand’s original specifications. The tooling was changed, and most of the affected receivers were modified to rectify the problem, and the rifles remained in use.

The first M1 rifles saw very limited issuance in the fall of 1937 when a total of 48 rifles were sent to five different Army bases. Since only a small number of the rifles were starting to be issued, few soldiers had seen an example.

The new semi-automatic rifle was certainly a revelation to the relative handful of soldiers who had the opportunity to fire the Garand, and the vast majority of those preferred it to the bolt-action M1903 rifle.

Many soldiers who had never been anywhere near an M1 bad-mouthed the rifle due to a lot of unfounded rumors floating around the barracks. Much of this angst was due to the simple fact that many people are reluctant to accept change, and the M1 rifle certainly represented change.

As the rifles began to see more field use, however, another problem surfaced. The “gas trap” gas cylinder proved to have several weaknesses. The screw that held the gas cylinder plug in place could become loose, thus causing the gas cylinder to become slightly misaligned. This could result in a bullet striking part of the gas cylinder and blowing it off the end of the barrel.

This wasn’t terribly common, but it did occasionally happen—and it needed to be fixed. Also, extensive firing could result in carbon build-up inside the gas cylinder. It was hard to get cleaning patches into the gas cylinder, and it was often necessary to disassemble the component in order to clean it properly. It has been said that it sometimes took a chisel to get out the accumulated carbon. Also, the gas cylinder was not a particularly strong attachment point for the bayonet.

John Garand, working in conjunction with the Springfield Armory Engineering Dept., developed a new gas system that was ready for preliminary testing in early 1939. Rather than trapping the gas after it left the muzzle, Garand’s new design had a port drilled into the bottom of the barrel through which the gas was channeled to impinge on the operating rod.

Interestingly, Ordnance Dept. and Springfield Armory documents of the period routinely referred to the gas systems as the old and new “front ends,” decidedly untechnical terms. A letter dated March 8, 1939, from Ordnance Maj. Guy H. Drewry to Lt. Col. Raymond Marsh at Fort Benning stated:

”The new front end has gone through a 10,000 round test and it has been found necessary to make some minor changes. These are primarily, however, to facilitate production. The functioning during the test was very good. We are planning to equip ten rifles with the new front end and send them to Benning for test and observation just as soon as we can. This will probably be some time within the next two or three months.”

The refinements on the new gas system apparently took a bit longer than originally anticipated, and Maj. Drewry followed up with a letter to Capt. H.G. Sydenham at Fort Benning on June 10, 1939:

“The new front end for the M1 Rifle is coming along fine. We expect to send down shortly to Benning eight or ten rifles with the new front end for test. The main trouble that we have had has been in determining the proper size of the gas port for the most efficient operation.”

This letter was followed by one written Oct. 4, 1939, from Maj. Drewry to Col. Marsh: “The ten U.S. Rifles, Caliber .30, M1, with the new front end were shipped from Springfield Armory on September 27, 1939, by express, so I imagine they have probably arrived there by this time and are being tested. I hope these tests can be completed as early as practicable so that we may obtain clearance for this design.”

Testing at Fort Benning (and elsewhere) did indeed validate the new gas system, and the design was recommended for adoption by the Ordnance Committee on Oct. 26, 1939. The Springfield Armory Annual Report for Fiscal Year 1939 contained the following details regarding the new gas system for the M1 rifle under the heading “The following developments in technological processes and engineering practices have been developed by the department during the past year:

[N]ew method of securing Gas Cylinder Assembly to the Barrel of the M1 Rifle and an improved method of trapping gases required for operation. The newly developed gas cylinder assembly not only provides a more rigid and positive positioning of the gas cylinder on the barrel but eliminates variations in the size of the gas orifice and greatly improves the accuracy of the piece. Ease of maintenance has been of paramount consideration during the design of the assembly and the cost to produce it will be less than that of the previous model.

In addition to the rifles sent to Aberdeen, a number of others were distributed to Frankford Arsenal, the Cavalry Board and the Infantry Board. The Springfield Armory Annual Report for Fiscal Year 1940 (July 1, 1939 to June 30, 1940) stated the following regarding the new gas cylinder:

Delivery of the re-designed front end for the M1 rifle started in June, 1940. At the present the machinery for the old front end is rapidly being adapted to the manufacture of the new components in greater quantities.

Even though the new “gas port” barrel was 24″ in length as compared to the 22″ barrel of the “gas trap” model, the overall length of the revised rifle remained about the same since the “false muzzle” of the original design was eliminated. The rifle’s weight of approximately 9 lbs., 8 ozs., was not affected by the change in gas systems.

Even after the order was given to change over to the new design, M1 rifles with the older gas system continued in production so that the existing supply of earlier parts could be used up. Thus, it was not until August 1940 that the last of the gas trap M1s came off Springfield Armory’s assembly line.

By this time, some 32,000 additional rifles of this pattern had been manufactured. It should be noted that this figure represents the number of gas trap M1s made after the new gas system had been adopted but before the tooling was changed to incorporate it into the manufacturing process.

A memorandum from the Subcommittee on Small Arms to the Ordnance Technical Committee contained the following information pertaining to the adoption of the new gas system. The memo makes it clear that the gas trap rifles already issued were to remain in service until substantial repair, such as barrel replacement, was required. The memo also disclosed the number of rifles that had been manufactured with the older gas system:

Reference a. covers the adoption of a new gas cylinder for the M1 Rifle. It recommends the adoption of the new design of gas cylinder for current manufacture. However, no mention is made concerning the disposition of rifles having the old style gas cylinders after the barrels thereof become unserviceable and require replacing. There were approximately 48,119 of the subject rifles manufactured with the old style gas cylinders and barrels.

Recommendations

This sub-committee recommends that the authorization be granted to replace the old style gas cylinders and barrels with the new style gas cylinders and barrels, as the old assemblies become unserviceable.

While this document reveals the number of gas trap rifles originally made, there are still some questions regarding the serial number range for these rifles. For example, it is known that some gas port rifles assembled in mid-1941 were in the 40,000 serial number range, and serial numbers as high as the 51,500 range have been reported by credible sources as original gas trap rifles.

This overlap in serial numbers between gas trap and gas port M1 rifles during this period was a case of the Ordnance Dept. using up gas trap parts still on hand in order to put as many M1 rifles into the hands of troops as possible, even if they weren’t of the latest design.

A surprising number of unaltered gas trap rifles saw service during World War II and were not updated to gas port configuration until sent to ordnance facilities to be rebuilt during, and after, the war.

After 1940, gas port M1 rifles that passed inspection at Springfield were stamped “SA” along with the initials of the Armory’s Commanding Officer. Unlike the “SA/SPG”-marked gas trap M1 rifles, the Final Inspection Stamps of the commanding officers of Springfield were also accompanied by the now familiar Ordnance Dept. “crossed cannons” escutcheon.

While the new gas cylinder was the most notable change in the design of the M1 rifle, numerous other modifications were made during the course of production.

These included elimination of the separate compensating spring, a change from a keystone spring to the more familiar “round-wire” spring and the incorporation of a buttstock recess that was accessed by a buttplate having a hinged trapdoor. It was found that the rear sight did not always hold the adjustments securely, and early in World War II the spanner nut on the windage knob was replaced by a “locking bar” that could be hand-tightened.

As the gas trap rifles were subsequently rebuilt and converted to gas port configuration, they were fitted with the updated parts. Typically, all that remained from a gas trap rifle after rebuild was the receiver, and even that part was modified to correct the “Seventh Round Stoppage” defect.

Despite the myriad changes made in the various components of the M1 rifle as production continued through 1957, the revised gas system was the only major modification of the rifle since its adoption in 1936.

It should be noted that even if the gas system had not been changed, John Garand’s rifle would still have been the best general-issue semi-automatic service rifle fielded in significant quantity by any nation during World War II. The change from the gas trap to the gas port system simply made a good rifle even better.

Today, the M1 rifle enjoys tremendous popularity with many collectors and shooters. For a collector, the acquisition of an original gas trap Garand is a worthwhile, but extremely elusive, goal. It is widely considered the “Holy Grail” of M1 collectibles, as well as a little-known, yet historically significant, U.S. military rifle.