Category: The Green Machine

The old Regular Army, part fairy tale and part dirty joke, was generally either ignored or disdained. But its people went about their work with a dogged humdrum gallantry—and when the storm broke, they helped save the world.

“What do I want to go back for?” Prewitt said wonderingly. “I’m a soldier. ”

“A soldier, ” Alma said. “A soldier. ” She began to laugh. “A soldier, ” she said helplessly. “A Regular. From the Regular Army. A thirty-year-man. ”

“Sure, ” he said.

—James Jones, From Here to Eternity

When Westmoreland reported to the 18th Field Artillery at Fort Sill, they put him to breaking remounts destined for pulling Model 1897 French 75s with wooden wheels. Sometimes he supervised horses grazing on the flat Oklahoma plains. He was then 2d Lt. William C. Westmoreland, fresh from the United States Military Academy at West Point, and his days of commanding an overseas force five times the size of the army he had entered were unimaginably far into the future.

His social duties, he found, were as demanding as his military ones. There were formal dances, failure to attend which would result in a black mark on his record, affairs at the officers’ club on weekend nights, participation in bridge games. Horses were all-important: shows, hunter trials, polo, Sunday-morning chases in pink coats, hunt breakfasts with singing of hunt songs and ballads. He had become a member of what was the seventeenth army of the world—as Chief of Staff Douglas MacArthur repeatedly pointed out to congressional appropriations committees. (When George C. Marshall officially became chief of staff, on the day Germany invaded Poland in 1939, it was said that the country had dropped to having the nineteenth army of the world.) Surpassing the United States in military power were, among other countries, Czechoslovakia, Turkey, Spain, Yugoslavia, Poland, and Romania.

Marshall was serving on the West Coast when ordered to Washington to take up his new duties. It was summer, and he asked if it was possible for the War Department to provide funds for Mrs. Marshall and him to go cross-country by train, avoiding travel via lead-footed Army transport through the blast-furnace heat of the Panama Canal. He did not make his request by telephone or telegraph; such money-consuming practices were forbidden except in cases of extreme emergency. Four letters went back and forth before the man he would replace, Gen. Malin Craig, was able to write that the cash had been scraped up.

The annual Army budget in those years, the years between the end of the First World War and the beginning of the Second, averaged in the $300 million range. That included provision for the Army Air Corps, whose pilots usually communicated with the ground by dropping notes wrapped around stones and checked their flight progress by swooping down to read town designations on railroad-station signs. The Army’s total research and development budget amounted to $5 million dollars when Marshall took over. That was one four-hundredth of what was going to be spent on the development of the atomic bomb.

It hardly amazed Marshall that the price of two railroad tickets was a matter of some importance to the Army he was soon to head. American military practice had always been to fight by using volunteers, quickly raised and as quickly disbanded, and to rigidly keep down all expenses in peacetime.

Only twice had this rule been abrogated. The first time was when Fort Sumter was fired upon. There ensued four years of unrestricted spending followed by Appomattox and the Grand Review of the Union Army in Washington, then the dispersal of its members home to spend the rest of their lives talking about how they licked Johnny Reb. (South of Washington the former opponents talked about the Lost Cause.) With the shedding of the uniforms blue and gray, the Army became an unseen distant force shepherding Indians about, occasionally shooting them, and, in the Spanish-American War, doing things in Cuba with the assistance of volunteers. The manner in which Regulars were regarded by the population was expressed by a turn-of-the-century congressional measure that made it illegal for taverns and hotels to put up notices saying No Soldiers Admitted. It is said, however, that parks near posts or bases bore signs announcing No Dogs or Soldiers.

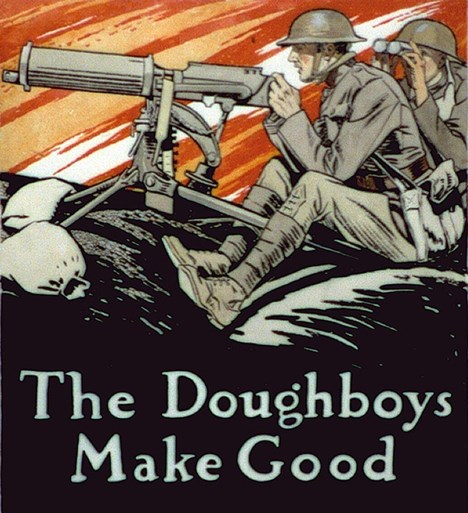

In 1917 there was a brief lemme-at-‘em thrust to Save the World for Democracy that saw college boys enlisting en masse. Then followed a vast disillusionment in which it was said that American entrance into the World War was a gigantic farce concocted by J. P. Morgan, the British, and the armaments Merchants of Death; that the United States should never have sent a man. The great four-million-strong doughboy army was gone to make money in the Roaring Twenties, but a little group of men stayed in uniform, keeping their number at the 120,000 range by taking in eighteen-year-olds who joined up for one of three reasons, or so it was said: They were given a choice by a judge of enlistment or prison; they’d knocked up a girl and had to get out of town fast; they were on their uppers, couldn’t think of anything else to do, and needed three hots and a flop. Recruiting officers learned that the end of the harvest season brought in men whose jobs had given out. Strikes or lockouts in the cotton mills also were good.

“Please, gentlemen, quiet, please,” the new men were politely asked while they milled about waiting to be sworn in. The oath taken, it immediately became “Shut up and pay attention, you lummoxes!” There were no centralized training posts; they learned on the job from noncoms. They got $21 a month—70 cents a day. (When the Depression took hold, pay was cut to $16.50 a month, with $1.50 taken out for laundry and a quarter deducted for the Soldiers’ Home in Washington, where retired enlisted men could go when their time was up.) Every company had a handful of leftover heroes of what in America was usually called the World War, as opposed to Britain and the Continent’s the Great War—men wearing a Distinguished Service Medal or Cross earned in 1918, or even the Medal of Honor, but now perennial and perpetual privates. There is often a difference between being a good fighter and a good soldier.

A great percentage of the men were from the South of mountain hollows or pine tree barrens and red soil-surrounded bleached cabins. Few had any family back home, or at least anyone who cared to write to them or perhaps even knew how to write. “It was a special occasion when a unit obtained a recruit who was a high school graduate,” Westmoreland remembered, looking back to Fort Sill in 1936. Forbidden to marry until they had attained the grade of sergeant (which could take a decade, for one served his first three-year hitch as a private and his second as a private first class, and then often stayed there), the rear rankers’ away-from-barracks social life was often confined to association with prostitutes. No sane and decent girl would risk her reputation and that of her family by even talking to a soldier.

The great moment for contact with the outside world was payday. By ten in the morning the money had been handed out and poker and crap games got going in the dayroom, which was normally off limits until the evening. By noon a certain number of men were out of money and out of the game, and their task became to seek out a 20-percent-man who would lend them something at that monthly rate with repayment the following payday. Every company had a couple of such bankers. Armed with their new funds, the losers at cards and dice took off. (Behind them, more fortunate players battled on for high stakes among themselves. Then, at dark, the big winners of each company would meet in the post’s monthly version of the World Series, with really colossal sums tossed down on the table.)

Outside the post, romances of sorts flourished on payday. The poet and critic William Jay Smith, improbably the son of a career corporal who now and then briefly rose to sergeant before being busted, remembered how at Jefferson Barracks, Missouri, prostitutes in satin evening dresses stood waiting at the trolley station near the gate. The women wore sneakers and carried blankets, the accouterments for visits to the nearby woods with their patrons. At other posts the custom transported itself to the point-of-product delivery; there were long lines in front of the whorehouses. Prior to lining up came drinking at saloons or speakeasies that lavished welcome upon payday soldiers but failed to know them a day or two later when the money was gone, photo taking at penny-arcade studios, the firing of .22s at a shooting gallery, fistfights with civilians or other soldiers. Then the girls.

When he was satiated, at least for the moment, it became a matter of importance for a man to get back to the post as speedily as possible. Contracting syphilis or gonorrhea was a court-martial offense, and failure to take what was termed a venereal prophylaxis could lead to a charge of failure to obey orders. Each of the Army’s more than 130 continental and overseas posts, bases, or stations had a particular place at the hospital or dispensary or infirmary marked by a green light burning twenty-four hours a day. You got filled up with ptargyrol, which you had to hold in for five minutes- not pleasant—and were given a tube of white ointment to smear on. You signed a form that was witnessed by the medic on duty. He kept a copy and gave you one. You had to state that treatment was taken within one hour of exposure. If you later turned up with a dose, you were in the clear with the authorities, seen as just someone who got an unfortunate break. (Syphilis is, after all, Hemingway once said, the occupational disease of soldiers and bullfighters.) But if you didn’t have the evidence you’d done the right thing, your sojourn at the hospital—Salvarsan and mercury shots, endless—was “bad time,” which meant it had to be served at the end of your regular enlistment, added on.

The day after payday the company or troop or battery commander and the first sergeant, “Top” and “First” to those serving under him, canvassed the local lockups, collecting men incarcerated for slugging someone from another unit, insulting women, annoying merchants, breaking windows. The gates of the guardhouse or, for real malefactors, the stockade, opened. (James Jones’s From Here to Eternity tells what Private Prewitt found there.) Sometimes soldiers who’d broken down in crying jags about seeing home so clear took their payday money and went over the hill. It never worked out. They either turned themselves in after a while or got caught. From 1920 to 1932 any civilian law enforcement officer who turned in a deserter got fifty dollars; through Depression economies it went down to twenty-five dollars in 1933. Once back, the men did their bad time making big ones into little ones—i.e., smashing up stones with a sledgehammer—and then had the bounty money deducted from their pay bit by bit when they were returned to normal duty.

In those years, that long-ago between-the-wars day when corporals wore white gloves for inspection, running their fingers over wall lockers or the tops of doors in search of dust, it would have been a long job to find a civilian who had a good word to say about the enlisted personnel of the United States Army. As with the slightness of congressional appropriations, that was wholly in the country’s tradition. During most of the life of the Republic, the American army, it was said, had scarcely been American at all, composed as it was of Irish or German immigrants of a completely uneducated type. What Wellington had termed his men at Waterloo, the scum of the earth enlisted for drink and booty, would have summed things up for most citizens, as would a description once offered about Frederick the Great’s parading hosts: a jail on the march. “The Army would be a fine place if it were not for the enlisted man,” an old-time officer once remarked to Brig. Gen. George Van Horn Moseley, MacArthur’s deputy chief of staff. Nothing was less likely than that a ranker would be found a romantic outcast of the Beau Geste Foreign Legion type, gone off to join the colors to forget a tragic love affair or by reason of incapacity to pay bills at the club for running through Father’s inheritance.

And the men never even did anything either. British troops garrisoning the Empire at least performed a useful function by tamping down the natives whose outland disturbances called for a punitive column winding its way upcountry now and then. But the American soldier? Why did he even exist? All through the 1920s and into the 1930s, any newspaper reader knew, there were international disarmament pacts, strongly supported pacifist movements, laws laid down for the abolishment of armed conflict. The novelists told of the utter futility of 1914-18, and antiwar plays did well on Broadway and on tour. Yet here were a group of men maintained at public expense who spent their mornings at practice with bayonets, sidearms, rifles, carbines, and artillery pieces—95 percent of the time “dry runs,” to be sure, for ammunition cost money— or running their horses around.

Or they mowed lawns and clipped hedges and whitewashed stones abutting the post’s roads or outlining the parade ground. It all seemed so pointless to any civilian who gave it a moment’s thought—a tiny number of people, granted. Even more useless appeared what soldiers did after lunch. Save for rare field exercises, there was no training. Instead the afternoon hours were spent in open loafing or in sports activities. Sports were very big. Every unit had its team, boxing, baseball, and football, and many a staff sergeant got his stripes not through leadership ability or military skills but because he could hit like hell, humans or a ball, or throw a pigskin and land it on a dime. Such were actually semipro athletes. Their work was to do what would bring victory for the team and a good mark on the record of the officer who coached it.

When evening came, all hands assembled and marched out for the flag-lowering ceremony, the band playing, bugles blaring and drums pounding, men sparkling, the shouldered and then present-arms 1903 Springneids with wooden stocks glittering from hours spent rubbing in linseed oil, brass eyelets on web belts polished, every tunic firmly buttoned, each campaign hat secured just so by its chin strap, artillery mules and cavalry horses scrubbed and brilliant. The flag came down. Dismiss. The men of the seventeenth army of the world went to the mess hall to sit until the table corporal ordered them to commence eating. Potatoes were the staple of the meal, that and a stew of meat and vegetables called slum, some beans, some corn bread, coffee. From 1922 to 1927 the government allocated thirty cents per day per man for food. By 1938 it was up to forty-three cents a day.

Their meal ended, soldiers sat around the dayroom reading magazines purchased by the company fund, listened to the radio, talked about last payday, talked about next payday, played cards for matchsticks, told each other they were getting out at the end of this hitch, talked about making corporal. At the overseas posts, in Tientsin in China where the 15th Infantry had been stationed for decades by protocol arrangements growing out of the Boxer Rebellion, and in Hawaii, Panama, and the Philippine Islands, the routine was the same except that in the last three locations one’s brawls took place under tropical moons and often featured the United States Navy as preferred enemy. When, after months at sea with no place to spend money, the fleet made port in Subic Bay or Pearl Harbor, the bars and whorehouses catering to servicemen tripled their prices. That left the soldiers out in the cold. This led to exchanges of opinion between men in khaki and men in bell-bottom white that concluded with the appearance of the shore patrol and the white-legginged and brassarded provost marshal’s people, with batons rising and falling on any convenient skull. Overseas duty had one important attraction: Things were inexpensive. There was a Panama place beloved by generations of soldiers where a man could get for half a dollar American a woman who would service him in a manner many of her Stateside counterparts refused, plus a glass of rum, a cigarette, and a shoeshine. Simultaneously.

It is hard, it is almost impossible, to talk about the officers in the same breath as the soldiers. As commander of the Army of Northern Virginia, Lee often wore an old colonel’s uniform, and Grant, we know, was in private’s attire with blouse buttoned in the wrong holes and lieutenant general’s stars sewn on at Appomattox. For the Army of between the wars such doings and concepts were inconceivable. Pershing was the model, Pershing who was the only soldier the public knew (how many today can name one of his subordinates?) and who positively glittered in his shining boots with gleaming spurs, polished Sam Browne belt, flawless brass and silver insignia, fitted breeches, and stern garrison cap. An officer was an Officer. And a Gentleman. They had all taken it in at the Point along with Duty, Honor, and Country.

They lived on a plane utterly remote from the men they commanded, always addressed in the third person. Will the lieutenant sign the report now? If the captain will step this way. (Familiarity breeds contempt, and so the word you for enlisted personnel was outré .) The Army’s officer corps of some twelve thousand dwelt in what was both a formal country club—and an informal old boys’ world. Dress blues, dress whites, sabers with glittering chain of nickel, shoulder braid, knowing how to put a horse over a jump, good form at tennis and at the bridge table, holding liquor like a gentleman, ability to tell a story well, rigid attention to courtesy calls and the leaving of cards on silver trays, and perfect posture— all co-existed with being openly flat at the end of the month (but up-to-date on bills, for a letter from a collection agency would bring a calamitous black mark on your record), boozing, fear that a superior’s wife wouldn’t care for your bride or that your kids might fuss, childish jokes at dinner with friends in your quarters, use of profanity unheard in the civilian world, substitution of the radiator for a chair and the floor for a table when household furnishings were late in arriving at a new post, and the perpetual, lifetime use of nicknames for friends made when young with whom the decades were served out—Ike, Brad, Georgie, Hap, Tooey, Skinny. (Old-timers still referred to Pershing as Nigger Jack for his early service with one of the two segregated cavalry regiments, even though during the World War the papers cleaned it up to Black Jack.)

Promotion was glacially slow. Patton was a major for almost fourteen years, and Bradley for twelve, Marshall a lieutenant colonel for eleven, Alfred M. Gruenther a first lieutenant from 1923 to 1935, as he wondered if when he got older, the Army would be large enough to have more than eight colonels. Working with troops meant essentially the same thing over and over for years: inspection of hooves and deflection of guns, charge at raised pistol and drill of infantry from squad column to skirmish line, and bellowing at men who offered sloppy salutes while all the time acting and being acted upon as if one were a great personage engaged in the most important of duties, chivalrous heir to the knighthood of the past at officers’ club hops or in attendance dinners there whose floral decorations and number of covers were carefully reported in the society section of the local paper and the Army and Navy Journal . Few officers were of the class of man who was commissioned into the regiment of the British army in which his father and grandfather and great-grandfather had served, nor were they seen abroad as professional soldiers, really, “Not as we understand that term,” remarked the future Field Marshal Harold Alexander of Tunis, but when they got some rank, they could live in great red-brick solid houses with huge kitchens, trunk rooms, high ceilings, and tall windows facing out across officers’ row to the manicured parade ground. Even a second lieutenant had an orderly or striker to polish leather and shine brass for dress or field uniforms. There were no fatigue outfits for officers. They did not exist.

One knew no civilians but worked with, played with, drank, and ate only with other officers, a brotherhood preoccupied with study of The Army Register to see who above might die or retire and so leave open a vacancy for filling. Creating a good record called for scoutmastership of a post Boy Scout troop, making sure one’s yard was in perfect order with not a weed to be seen or a child’s toy, diligent practice for the tennis tournament, rehearsal for the amateur theatricals, not slouching in the officers’ section of the post movie theater on better done-up seats than those for the enlisted men, with slipcovers. The display of equipment on Army Day was an important matter, with decisions to be made about floral displays on the floats. Wives gave costume parties and joined sewing circles and the post garden club, sedulously avoided any appearance of ever being overly tipsy, and put as good a public face upon the marriage as possible despite what the actual circumstances might be, for marital discord would find its way to damning mention on the efficiency report.

Church attendance was, if not mandatory, then the next thing to it. (Most officers were adherents of a religion known as “Army Protestant.”) Display of family money was a delicate matter. George S. Patton, who had a lot and married more, kept a yacht and a string of one dozen polo ponies, forgoing the usual utilization of Army horses for the sport, but Mrs. Mark Clark remembered all her life how a colonel’s lady expressed indignation that a junior officer’s wife should have elegant silver on her table and additionally drive a fully paid-for new car, the gift of her parents. There were constant bridge luncheons to give and to attend, Lady Bountiful attention to sick wives or children of the enlisted men of one’s husband’s unit, gracious applause for the winners of soldiers’ competitions in hand-grenade throwing, rope climbing, broad jumping, wall scaling, marksmanship mounted and marksmanship afoot, and wrestling on horseback. For Saturday dress parades the officers’ wives sat on the grandstand wearing hats and gloves to see the troops go by with snapping colors and guidons, looking from afar like smart toy soldiers, chocolate soldiers, tin soldiers all in a line.

The business of an officer is efficiently to slay the enemy, but for the entire period between the two world wars the United States Army motto might well have been Thou Shalt Not Kill. After the brief post-armistice intervention in northern Russia up until the moment when weapons were rushed up to the tops of barracks buildings for discharge at the Zeros swooping through Hawaiian skies on Pearl Harbor Day, the Army fired not a single bullet at anyone. Its only action of any kind at all came when the 3d Battalion of the 12th Infantry, the 2d Squadron of the 3d Cavalry, the 1st Platoon of Company B of the 1st Tank Regiment, and the headquarters company of the 16th Brigade, eight hundred men in all, formed at the Ellipse in Washington to drive away what was termed the Bonus Army, unemployed veterans of the World War who had come to the capital to ask that money scheduled to be given them in 1945 should instead be paid out in the summer of 1932. Chief of Staff MacArthur, against the advice of his aide, Major Eisenhower, took personal charge. (An abiding legend has it that the entire operation was held up long enough for Eisenhower to rush to Quarters Number One at Fort Myer across the Potomac in order to pick up MacArthur’s “pinks” with English boots and field tunic with rows of ribbons from the left breast pocket to the epaulet.)

The cavalry commanded by Major Patton came clattering down Pennsylvania Avenue with sabers drawn, followed by the infantry with fixed bayonets and tear gas and a few tiny tanks. A number of the veterans were swatted with swords held flat, a few pricked with bayonets, some were tear-gassed, and the Bonus Army was gone. No shots were fired by the Army. The matter put MacArthur in poor odor with the public, but when Hoover left and Roosevelt came in, he remained as Army head. As such he battled against Roosevelt’s announced intention to dehydrate the Army even more than it was by cutting the annual appropriation to below $200 million. What is that, about a fifth of the cost of one of today’s Stealth bombers? The two men had it out in the White House.

After the United States had lost the next war, MacArthur remembered himself telling Roosevelt, “and [when] an American boy, lying in the mud with an enemy bayonet through his belly and an enemy foot on his dying throat, spat out his last curse, I wanted the name not to be MacArthur, but Roosevelt!”

“You must not talk that way to the President!” Roosevelt roared, and MacArthur apologized and offered his resignation, which Roosevelt refused to accept. They’d work something out, the President said, and MacArthur left him, got partway down the White House steps, and threw up.

The great American military issue of the twenties and thirties was the horse. Since war began, the horse had been the indispensable adjunct of the commander. An officer did not walk. He rode. There was the “certain indefinable social prestige” that the man on horseback had always had over the man on foot, wrote the chief of cavalry Maj. Gen. John Herr. A charger marked the officer as the cavalier, hidalgo, gentleman—the leader. Most of the prominent soldiers of the World War had been cavalry officers. But what had the horses done in the mud and barbed wire and machine gun- and howitzer-swept reaches of the Western Front? Machine tenders could in a flash wipe out a squadron of mounted knights at arms. That was the problem. The statue in the park or plaza showed Marlborough on a horse, Eugéne of Savoy, or Stuart or Sheridan, but a clanking tank could be heard in the distance.

The Cavalry Journal set its face against engines, gasoline, garagemen. In issue after issue, for more than twenty years, the magazine presented its case: Unlike horses, tanks and armored cars have noisy motors and must use lights at night, and so violate the scouting necessity to remain unobserved while observing. No engine could utilize grass for fuel. Boulders or swamps entrap tanks or artillery trucks and leave their crews as occupants of iron tombs, hoping someone on horse-back or foot will come along and rescue them. Vehicles cannot swim. Peeking through slits, tankers aimlessly spit out bullets while pitching about, with directed fire on the move an impossibility. Motor vehicles knock down trees, and so their path can be seen from the air, while horses slip through forests. There are no development or experimental expenditures for horses.

The entire Western Front experience, The Cavalry Journal said, had to be viewed as a singular and particularized event unlikely to be repeated, one that would never have occurred if the Germans had understood the proper use of the cavalry that could have won the Battle of the Marne and taken Paris in 1914. Perhaps the entire agitation against old dobbin was a scheme of the automobile companies.

Asked by appropriations-committee congressmen if they intended to lead charges against modern machine guns, the cavalry chieftains replied that they would not charge en masse while pointing out that it was difficult to stop a horse coming directly at you even with a machine gun, for its vital organs sat behind a foot of solid flesh. The great debate went on as the mechanized cavalry came into existence, slowly to join in uneasy partnership with the real cavalry. The Cavalry Journal stuck to its guns, joyously reprinting a facsimile of a 1938 Washington Post report on how Spanish Civil War Moroccan horsemen seized the heights of a mountain near Teruel, overwhelmed the fortifications, and left three thousand enemy dead on the slopes, and it was pointed out that at the Pine Camp, New York, maneuvers of 1935 a full 33.3 percent of the United States Army’s serviceable modern tanks, handmade prototypes, were put out of action without any simulated fire being directed at them: one broke down through mechanical failure, and the other immobilized itself on a tree stump. The magazine quoted what Field Marshal Lord Haig had said about horses, Pétain, Ludendorff, Napoleon, all the latest authorities and all the ancient masters of the field; illustrated how machine guns could be off packhorses and ready for action on tripods in less than a minute; reported on new endurance-ride records; and gave the results of cavalry-post gymkhanas featuring musical chairs, bareback riding, and the musical ride. Artillerymen and cavalrymen kept their flaring breeches and high boots in place of trousers and shoes, and so did the Air Corps officers regulations demanded spurs be removed before entering a dirigible—but the world seemed to be wandering away from The Cavalry Journal , and the day was coming when it would change its name to Armor .

But then, many things were coming. We know it now. We know that officers who have spent their youth and middle age unknown to anyone will of a sudden find the fate of millions hangs upon their decisions, as they bestride the globe, dictate terms, govern conquered countries, consort with prime ministers and dine in palaces with kings and queens, go on to be corporation presidents, be elected to and appointed to the most powerful posts their country possesses, and finally retire wreathed in glory for the writing of their memoirs.

Back then could they have dreamed of such things? What kept them in the Army those long and dismal years, the two decades of going nowhere? Partially it was the schools. Officers took courses in foreign languages and the Bombardment Course and Motors Course, went to the Chemical Warfare School and the advanced school of their arm, the Infantry School, the Field Artillery, the Cavalry.

Then, ten or twelve years into their careers, the best were taken for the Command and General Staff School at Fort Leavenworth. The entire post was kept as silent as possible, Mrs. Mark Clark remembered, and the wives spoke in whispers and shushed the children while the husbands and fathers worked on plans for paper forces that took into account the disposition of a great army and the advances, withdrawals, river crossings, amphibious landings it must make, its unit integrity, logistics, communications, administration, and supply while operating over mountains, gaps, plains. They planned great campaigns against great enemies and then, when finished at Leavenworth, went back to marking time, worrying about camp hygiene and how the team would do, the AWOL rate, and how the colonel would mark their efficiency reports. After a few more years, when they had about twenty years in, the very best were sent to the Army War College at Fort Humphreys, now Fort Lesley J. McNair, in Washington. That was the top, with preparations made there for command on the highest level, great speculations on how they would deal politically with Britain, economically with Japan, what policy should be followed with Germany.

The others who did not get to the two top schools soldiered on. Not everyone is cut out for the peak of his profession. Uniting such with those for whom one day boulevards would be named, to whom foreign governments would award Grand Cross of this and Order of that, there was something else. It brought in even the enlisted men—even them, or at least most of them. An Army post in the twenties and thirties was one of the most boring places on earth, the corporal’s son William Jay Smith felt, but perhaps, he thought, there was a rhythm to be heard if you listened carefully in those years of the eye of the hurricane between the two world wars, and it gave meaning to lives that otherwise might have known none. For there was retreat with the flag fluttering down the polestaff, the beat of a thousand feet hitting the ground at the same instant and a thousand hands slapping rifles, the spit-and-polish uniforms for which even privates bought custom-made shirts and better brass and belts and leggings than the government issued, and the drums rolling and bugles calling, white-gloved honor guards for the uncased colors, the sweet horses men learned to love, memories of group singing on the poop deck of the transport Ulysses S. Grant as she creaked along at her slow ten knots an hour, four times a year, out to the Pacific ports and back, the swagger and sharpness rooted down deep in things better not talked about, such as discipline, honor, courage, austerity, fortitude, duty and the country and the profession of arms that made you different from everyone else. There is something about a soldier.

The war was coming. It would come too late for the high officers, Marshall knew. They were old and had minds too set in outmoded patterns, he told an intimate one month after taking office in 1939. Who would replace them? “I’ve made a little list,” Marshall said. “I’ve looked over the colonels, lieutenant colonels, and some of the majors.” Of 1939’s twenty-one major generals of the line, not a single one did anything of note in the Second World War with the exception of John L. DeWitt, whose contribution was to supervise the internment of the West Coast’s Japanese-Americans. Many of the old generals went to their graves hating Marshall for not giving them something big to do, for they had been his friends for years, their wives had entertained him at dinner. But something greater was involved: It was the Army and the country. The men for whom elementary and high schools are named were on his little list.

The war was coming, and then it came. In Honolulu after the Japanese planes flew away, Schofield Barracks’ men were trucked through the streets for the beaches to repel an expected invasion. Girls waved and threw kisses, and the mothers of those girls urged them on.

Then came the entrance of more than eight million men into what had been an army of a little more than one hundred thousand, with USO shows and stage-door canteens and little old ladies inviting servicemen to their houses for nice home-cooked meals on Sundays, and men buying them drinks while Red Cross people at the train depots offered free packs of cigarettes, “tailor-made,” not like the rolled ones the Regulars always used to smoke; and all the equipment was redesigned, the helmets, packs, web gear, barracks bag, shelter halves, everything; and in 1942 Yank , the GI weekly, run by and for the ex-civilians, defined the words Old Army as a group of persons who spoke in sentences inevitably beginning with “By God, it wasn’t like this in the ——”

America’s enduring Model 1911 .45-cal., semi-automatic pistol remains a landmark sidearm more than a century later. Yet how it was introduced to service and typically carried by soldiers, sailors and marines before World War I remains lesser known.

Self-loading handguns became possible with the French invention of smokeless powder in 1884. Two blue-blooded Austrians, Karl Salvator and George von Dormus, patented their pistol in 1891, which held five rounds of proprietary 8 mm ammunition. It failed to find a market, but an improved version by another Austrian, Josef Laumann, entered production at Steyr the next year.

Thereafter, customer interest grew fairly quickly. In 1894, Hugo Borchardt’s C-93 in 7.65×25 mm attracted buyers with its eight-round detachable magazine, followed by Paul Mauser’s iconic “Broomhandle” in 1896, with ten rounds of 7.63×25 mm carried internally.

For the most part, the decade produced largely dead-end designs from Germany, Austria, Belgium and Spain, until Georg Luger arose. His 9 mm chambered P08 (for 1908) was first accepted by Switzerland in 1900, then by Germany along with many other nations.

In the United States, John M. Browning filed his first pistol patent in 1895, leading to the Belgian firm Fabrique Nationale’s hammerless .32-cal. Model 1899, followed by the enormously popular Model 1900 in .380 ACP. Retaining the detachable magazine but with grip and thumb safeties, the Model 1903 was produced in .32 and .380. Between them the Models 1900 and 1903 probably sold more than 850,000 units.

Placed in context, the .45 ACP emerged at the end of more than a decade of sidearm development. The M1892 was the first U.S. double-action revolver with a swing-out cylinder, chambered in the anemic .38 Long Colt. Adverse reports from the Philippine Insurrection, fought from 1899 to 1902, led to the M1909 in .45 Long Colt. A succession of variants emerged, with the stocks of the M1903 narrowed to provide an improved grip.

The stage for the M1911‘s development and adoption was set in 1907, when an Army board decided to replace its standard-issued revolver. Colt and Browning had collaborated on a nascent .41-cal. pistol round, but the Army’s Thompson-LaGarde ballistics tests of 1904 influenced development. Consequently, Browning modified the new cartridge as with a 200-grain, .45-cal. bullet, launched at 900 f.p.s.

The round appeared in the prototype Colt Model 1905, and after extensive testing by military and industry representatives, the final combination yielded the classic .45 ACP cartridge, with its 230-grain projectile launched at upwards of 850 f.p.s.

Army Ordnance concluded, “After mature deliberation, the Board finds that a bullet which will have the shock effect and stopping power at short ranges necessary for a military pistol or revolver should have a calibre not less than .45.”

Several aspirants entered pistols chambered for the new cartridge, and after elimination of other designs (including semi-auto revolvers), Colt’s and the Savage M1907 entries contended for the government contract. In the end, the final selection trial was not even close. The Colt ran flawlessly, while the Savage sustained dozens of stoppages.

As noted by American Rifleman’s predecessor, the April 1911 issue of Arms and the Man, declared, “the good old revolver became obsolete, and in its stead there was marked for the holsters of this Nation’s defenders the .45 Colt’s automatic; the latest, the most deadly, the finest and the best hand arm which had yet to be produced by man.”

Late in the final design process, the Army requested a thumb safety, which Browning added shortly before production began. The service requirement for a grip safety already was met, as Browning’s M1903 set the pattern for the military. Thus, the M1911 .45-cal. pistol evolved in a golden era of small arms design.

The Model of 1911 was adopted that March, with 21,000 delivered through December, including Navy and Marine Corps orders. Aside from the semi-automatic Mauser and Luger pistols, in the same period of time most nations were still introducing bolt-action service rifle designs.

Britain having adopted the Lee-Enfield rifle in 1895 and Germany’s Mauser designed Gewehr 98 came three years later. America had only adopted the classic Springfield M1903 rifle eight year prior.

Troops quickly noted the weight difference. The M1892 revolver weighed barely 2 lbs., while the Colt M1911 weighed nearly 2.5 lbs. with empty magazine, which may partly account for the decision to mate the pistol and holster to the sturdy 1910 pattern duty belt.

The Colt was carried in the M1912 holster, with a twin magazine pouch. Accessories were adaptable to the standard belt, which was frequently updated. Usually it was made of webbing or canvas duck, featuring rows of three vertical grommets to accept hooked hardware for holsters, canteens, and bayonets. Most of these pistols were produced with a lanyard loop in the butt, mainly for cavalry use.

In a 1913 article, Ensign C.E. Van Hook, an influential Navy instructor noted, “Eternal vigilance is the only price of safety.” Yet he commended the semi-automatic, partly because: “The trigger pull always remains the same, which is a decided advantage over the disconcerting double action of the .38-cal., and makes it a great deal more accurate for rapid firing.”

As issued, the Colt M1911’s trigger usually lets off at 6 to 7.5 lbs. Van Hook also noted “(the pistol) may be loaded with greater ease and rapidity. This takes into consideration the fact that under service conditions a number of extra clips, loaded and ready for instant use, would be carried in a specially designed belt.”

The M1911’s large frame caused problems for many users accustomed to the revolver’s smaller size. The Naval Institute Proceedings article observed, “One very simple way of overcoming most easily this short finger contingency lies in using the middle finger as the trigger finger. By using the middle finger, even without any previous practice, the shooter can get a better and freer purchase on the trigger.

Moreover, the middle finger is normally stronger than the index finger thus enabling the shooter to execute a smoother trigger squeeze. Let us assume that you are using the middle finger to “pull” the trigger. You will find it convenient to place the index finger either alongside the slide or on the receiver, depending on your own finger length.

However, the Army Ordnance manual of 1912 noted, “The trigger should be pulled with the forefinger. If the trigger is pulled with the second finger, the forefinger extending along the side of the receiver is apt to press against the projecting pin of the slide stop and cause a jam when the slide recoils. Additionally, some military teams allowed carving finger grooves in the 1911’s stocks for improved control, especially in rapid fire.

In 1926, the Army accepted modifications in form of the M1911A1, with an arched mainspring housing, a shorter trigger and frame indents behind the trigger. The annoying problem of hammer bite was largely eliminated with a shorter hammer spur and longer grip safety. However, many shooters preferred the original flat mainspring housing for greater purchase on the grip, and sometimes could retro-fit the original housing.

The Ordnance Departed listed muzzle velocity of 230-grain bullet at 802 f.p.s., penetrating 6″ of pine at 25 yards. Remarkably, trajectory was charted to 250 yards. The maximum ordinate was 4.29 feet (51.5″) at 126 yards. “The trajectory is very flat up to 75 yards, at which range the pistol is accurate.” (As a side note: General Joe Foss’ Air Force Reserve M1911A1, manufactured in 1944, grouped with 2″ extreme spread at 20 yards, but 8″ high.)

Reporting on range tests the manual said, “This pistol has been fired 21 times in 12 seconds, beginning with the pistol empty and loaded magazines on a table. Firing at 25 yards at a target 6 feet by 2 feet under the same conditions, 21 shots were fired in 28 seconds, making 21 hits with a mean radius of 5.85″.”

(Hatcher’s Notebook, page 421, described mean radius as the average distance of all shots from the center of a group; mean radius usually measured one-third of a group’s diameter.)

When action seemed imminent, the Army’s 1912 Description of the Automatic Pistol suggested topping off to eight rounds. The method seems peculiar today: with the magazine removed, lock the slide open and insert a cartridge in the chamber.

Trip the slide release, thus seating the round. Then a full-up seven-round magazine was inserted. It’s unknown how often loose rounds were available in the field. A far more likely technique was chambering the first round off one magazine and reloading with a full mag to bring the total to eight.

Addressing safety features: “The automatic grip safety at all times locks the trigger unless the handle is grimly grasped and the grip safety pressed in. The pistol is in addition provided with a safety lock by which the closed slide and the cocked hammer can be at will positively locked into position.” Decades later, speaking of the grip and thumb safeties, former Marine Lieutenant Colonel Jeff Cooper insisted, “If the 1911 were any safer it would be almost useless as a weapon.”

Decades of gun lore hold that the services originally carried the M1911 “cocked and locked,” or in today’s parlance, condition one. Presumably the policy changed after some negligent discharges. Allegedly, Lt. George Patton fancied himself a gunsmith and “improved” his automatic by filing the sear with exciting consequences, hence his devotion to revolvers. However, documentation indicates otherwise.

Contemporary sources heavily indicate that cocked and locked was only advocated facing imminent threat. The Ordnance manual noted that with a round chambered, “The slide and hammer being thus positively locked, the pistol may be carried safely at full cock, and it is only necessary to press down the safety lock (which is located within easy reach of the thumb) when raising the pistol to the firing position.”

However, Ordnance also advised, “Do not carry the pistol in the holster with the hammer cocked and safety lock on, except in an emergency. If the pistol is so carried in the holster, cocked and safety lock on, the butt of the pistol should be rotated away from the body when withdrawing the pistol from the holster in order to avoid displacing the safety lock.”

The problem, of course, is that it’s impossible to schedule an emergency. It was especially true in combat zones where enemy infiltrators or trench raiders might appear suddenly, at close range, often in darkness. Other concerns involved guard duty at a base entrance or building where emergencies seldom arose but the potential still existed.

The cavalry’s 1940 pistol field manual addressed modes of carry (page 19): “In campaign, when early use of the pistol is not foreseen, it should be carried with a fully loaded magazine in the socket, chamber empty, hammer down. When early use of the pistol is probable, it should be carried loaded and locked in the holster or hand. In campaign, extra magazines should be carried fully loaded.”

More than a century before the bane of today’s gun writers, the U.S. Government initiated the semantic heresy of referring to a pistol as a “revolver” and a magazine as a “clip.” An interwar Navy instruction advised, “Take the revolver in your right hand and the clip in your left. Show him how to insert the clip, trip the slide, inject the first round into the chamber, etc.”

The director of cavalry stipulated that mounted pistol exercises “will be carried on during the entire year.” Furthermore, drill would involve simulated firing at different objects at all gaits from walk to gallop.

Most targets were positioned at five to seven yards so troopers were required to engage right and left front; right and left flank; and right rear, the left hand of course holding the reins.

Anyone who has watched a SASS mounted event knows the common cavalry technique: leaning toward a front-aspect target while half rising in the stirrups, thrusting the pistol forward in the most direct line, wrist rigid, and forcing the right elbow to the left in vertical plane with wrist and shoulder. Trigger control was to be coordinated with start of the thrust, “He selects his target, fixes his eyes upon it with concentrated effort, catches sight of the target over his barrel, and squeezes his trigger with steadiness and precision.”

Live-fire drills showed the importance of follow through. Most misses were attributed to troopers’ failure to keep eyes on the target until after the shot was fired.

Concentration was paramount. Perhaps understandably in the midst of a cavalry charge, riders tended to look for the next target an instant before the round went. At all times troopers were strongly advised to keep the muzzle well ahead of the horse’s face for obvious reasons.

The manual devoted two pages to training horses not only around gunfire, but getting them accustomed to unusual sizes, shapes, and colors.

Long experience showed the wisdom of gradual exposure to unfamiliar objects and conditions, most often in groups rather than individually. Blanks and live fire were introduced as the mounts grew in confidence. Dismounted cavalry courses were fired at 15 to 50 yards, frequently walking toward pop-up targets. Various dates have been cited for the M1911’s combat debut, as early as 1913, but the most likely seems to be Marine Corps use in Haiti from 1915 onward.

In whole or in part, at least thirteen Army men earned the Medal of Honor with M1911s in World War I. Two Marines used Browning products twelve months after the armistice as Lt. Herman H. Hanneken and Cpl. William R. Button wielded both the M1911 and BAR, respectively, in their Medal action against Haitian rebels.

Since then, the M1911 has appeared in well over 120 theatrical movies through 2021, plus hundreds of television movies and episodes. That compilation excludes Commanders, Series 70/80s, other manufacturers, blank-firing copies, and portrayals in cartoons and video games.

In the 1969 film The Wild Bunch, a German advisor to the Mexican general notes that the Americans carry handguns “that may not be acquired legally.” In fact, the Colt Commercial “Government” models were marketed in 1912, with an initial run of 1,899 pistols.

The civilian market has only expanded in more than a century. Some 110 years later, the M1911 repeatedly finishes atop reader polls as “the most iconic American handgun.” Last year, Shooting Illustrated placed the M1911 ahead of the CZ 75 and Beretta 92, and even the classic 1873 Single Action Army. The fanfare of the M1911 shows no sign of abating.

Henry Mucci and the Rangers – from The American Exprience

Mucci was so charismatic you couldn’t believe it… If you ever had to go to war, that’s the kind of man you wanted to go with.” — Alvie Robbins, PFC.

We all would have died for him, he was the very best.” — Vance Shera, Sergeant.

We knew he was selling us the blue sky, but we would have followed him anywhere.” — Robert Prince,<;C Company Captain

Extraordinary Fighters

General Walter Krueger and his top G-2 man, Horton White, were the ones to choose Mucci. As Krueger and White considered the raid, they knew they would need an elite fighting force. Hampton Sides, author of Ghost Soldiers, writes: “[They] would need a group of men trained in stealth techniques and the tactics of lightning assault.

The expeditioners must be in exceptional physical condition, as they would have to walk some 30 miles on foot in each direction, marching around the clock. They would have to be versatile, self-reliant, and extremely proficient with light arms, as the odds were better than good that they would encounter major enemy resistance along the trek.”

Intensive Training

Mucci had just such an outfit. In fact he had trained them: the 6th Ranger Battalion. Mucci was a man of vision. It was he who took the unit of Army mule skinners and turned them into the elite jungle fighting force known as the Army Rangers. For one year, in the mountains of New Guinea, Mucci trained his team, one of the first American special operations fighting forces.

Mule Skinners Become Rangers

The men Mucci had started with were for the most part boys from the farms and ranches of middle America — big, strong men. Known as “mule skinners,” they had been recruited to train in the mountains of New Guinea with heavy artillery carried on the backs of pack animals. By 1944, the Army considered the mule skinners obsolete, and General Krueger was looking to train a new special unit. Mucci was his man.

Testing Physical Limits

Ranger training under Mucci bordered on inhuman. A boxer, judo-expert, athlete, and former West Pointer, Mucci believed in training his men to the absolute limits of their physical capacities. He personally taught them all aspects of fighting: hand to hand combat, knifing, bayoneting and marksmanship. He led them on torturous exercises across the tropical New Guinea jungles, through treacherous rivers, and up mountainsides in the ferocious heat. Jungle combat, night combat, amphibious combat; Mucci taught and reveled in it all.

John Richardson, 6th Army Ranger, recalled: “I thought he was going to kill us. He called us rats, he called us everything but a child of God. And he told us, “I’m going to make you so d—– mean, you will kill your own grandmother…. I wondered why he was putting us through so much, but before it was over, there was no question about it, I knew why. And once he got us trained and picked out, he loved us to death. And there wasn’t anything too good for us…. He knew what he was doing when he was training us.”

Slave Driver — With a Purpose

Bob Anderson, 6th Army Ranger remembered, “He worked us so hard that sometimes I’d think I hate that man and I’d double-time back to my camp and say, ‘You can’t kill me, I can do more. You can’t give me enough, I can do more than you can give me.’ So he had us in shape and once he got us trained he was the nicest man you ever saw. But he knew how to train men.” No doubt, Mucci got his men in peak physical condition. They were ready for the raid. They were ready for anything.

Superb Leader

Sometimes the fit is perfect. Mucci was the right man to train and lead the Rangers. He had all the qualities of a superb military leader: he knew men, he had vision, and he was decisive. Robert Prince said, “He made a Ranger battalion out of a bunch of mule skinners, and he inspired us and trained us — and any success we had belongs to Colonel Mucci.”

Honors

The rest is history. Mucci’s actions and decisions on the raid were flawless. General Douglas MacArthur awarded Mucci the Distinguished Service Cross and said that the raid was ” magnificent and reflected extraordinary credit to all concerned.” The military promoted Mucci to full colonel.

National Hero

Upon his return home, Mucci was treated as a national hero in his home town of Bridgeport, Connecticut. He unsuccessfully ran for Congress and later became an oil representative for a Canadian firm in Bangkok. An athlete till the end, he died at 86 in Florida from injuries related to swimming in rough surf.

As America geared up for war, the economy of building a wartime army was overwhelming. Tanks, aircraft, soldiers and weapons—all would consume huge resources, and manufacturers were challenged to reduce costs wherever they could. The arms industry was one area where the designers showed great creativity and were able to place function over form to accomplish their mission.

One of the more expensive (and iconic) weapons at the start of the war, the Thompson submachine gun, became a prime target for cost savings. In 1939, the M-1928 A1 Thompson cost the government more than $200 each—more than four times the monthly wages paid to a typical soldier. By 1942, design and production changes had brought the Army’s price down to around $75, and the final M1A1 variant hit a low price of $45 per copy by 1944.

Even so, in 1941 this was excessively expensive for a single weapon, so the War Department sought out a cheaper solution. That solution, the M-3 “Grease Gun,” came in at around $18.50 each, a savings of 90 percent.

As the war came closer to American shores, the U.S. Army Ordnance Board considered what was happening in Europe on the weapons front, including the German MP40 Schmeisser and the British Sten gun, and initiated a study to develop its own easy-to-make submachine gun. Early in 1942, the Army submitted a list of requirements for the new weapon, and Ordnance solicited a list of requirements from both the infantry and cavalry branches for a shoulder-fired weapon with full- or semi-automatic fire capability, in caliber .45 ACP.

Resting in a German house after a patrol, GIs keep their weapons, including two M-3 “Grease Gun” submachine guns, close at hand.

Resting in a German house after a patrol, GIs keep their weapons, including two M-3 “Grease Gun” submachine guns, close at hand.The list of requirements from each branch were then reviewed and modified at Aberdeen Proving Ground, and a tentative specification released to bidders. The initial T-15 specification of 1942 was for an all-metal weapon of stamped sheet-metal construction to fire the Army’s standard pistol cartridge (.45 ACP); to be designed for inexpensive production with a minimum of machining; and featuring both semi-automatic and fully automatic fire ability; a cyclic rate under 500 rounds per minute; and the ability to place 90 percent of all shots fired (from the standing position in full-automatic mode) on a 6×6-foot target at the combat range of 50 yards. The standard to which the new weapon’s performance was to be compared was the M-1928A1 Thompson, the “Tommy Gun.”

General Motor’s Inland Manufacturing Division in Dayton, Ohio, was just one of several companies that took on the challenge of developing this new weapon. Inland’s design team was already involved in the production of the M-1 carbine, so the chief engineer made this a personal project to plan for tooling and production.

The original War Department specs were simplified in late 1942 to remove the semi-automatic fire capability, and to propose an option to convert the weapon’s original caliber to the commonly available 9mmx19 pistol round that was used by both the Axis and Allied forces. The new specification for this dual caliber weapon was numbered T-20.

Five prototype models of the .45 T-20 and five 9mm conversion kits were built by GM’s Inland Manufacturing prototype shop and submitted for testing in November. At the Ordnance Department trials, the GM submission completed the endurance test with only two failures to feed in over 5,000 rounds fired. In the accuracy portion of the tests, the GM design scored an admirable 97 out of 100 possible hits on the 6 x 6-foot target. Then the real trials began.

Airborne Command, the Amphibious Warfare Board, the Infantry Board, and the Armored Forces Board were all encouraged to look at the best of the new designs. Each branch was told to independently test the T-20 prototype weapons, to see if this new, inexpensive weapon would meet their needs. All four review boards rated the basic GM design as “acceptable,” with similar suggestions and concerns.

All liked the short, handy size and reduced overall length, but all found fault with the GM-designed magazine and feed system, apparently due to the short, wide follower in the magazine that tended to tip or jam under hard use. The cocking handle was deemed too fragile, and the magazine could be difficult to fully load.

In spite of these faults, the T-20 was formally approved by the Ordnance Department for production in December 1942 as the “U.S. Submachine Gun, Caliber .45, M-3.”

The contract to build this new weapon was issued to the parent organization (GM), which proposed that the Guide Lamp plant in Anderson, Indiana, be the fabrication location, as they were familiar with metal stamping and welding operations and were not working at capacity (according to WPB inspectors). In 1942 this factory was producing blackout lights for Army trucks, M-2 HMG barrels, and parts for the P-39 Airacobra aircraft. With this contract, the Guide Lamp plant was at full capacity, with only 16 percent of the plant capacity dedicated to M-3 production.

When the exclusive contract was given, Guide Lamp produced a total of 606,694 of the M-3 variant sub-machine gun in 1943 and 1944. With no significant changes, the T-20/M-3 was produced as submitted. Even the balky 30-round magazine was put into production as submitted in the interest of expediency. Because of the prework done by the team at Inland, the first guns were able to be submitted for inspector approval within 45 days of the contract.

It was planned that the “Grease Gun” (so called because of its resemblance to the type of tool used by mechanics to lubricate a vehicle’s chassis and axles) or “Buck Rogers Gun” as it was nicknamed by the soldiers, would be produced in numbers sufficient to cancel orders for the more expensive Thompson submachine gun and to allow the Army to remove the Thompson from frontline service.

Due to production delays, design changes, and tooling problems, however, the M-3 never achieved its full potential during World War II, and purchases of the Thompson continued until February 1944. Considering the much longer service life, it is no surprise that the Allies put more than 1.5 million Thompsons into wartime service, outnumbering the M-3 by nearly three to one.

What did the Army get?

This new and inexpensive M-3 SMG used many automotive production-line processes to keep costs under control. Like the German MP40, the receiver was made of two deep sheet-metal stampings welded together to form the tube for the bolt. The small parts of the firing mechanism were steel stampings, castings, and pressings, with only three machined parts in the whole weapon. The barrel had to be rifled from formed steel tubing, the face of the bolt had to be precision ground, and the threads to retain the barrel were ground, but the balance of the gun was stamped, pressed, and welded.

The magazine was formed from sheet stock, and even the sights were stampings. (A creative note: The sights on the M3 were finished in the test-firing stage when a special drill bored the peep sight hole to align with where the gun put the bullets—not trying to move the sights to meet the point of impact after the fact.)

In the field, the weapon could be disassembled without tools for cleaning or conversion to 9mm. It was simple to work on, reliable, and cheap to build and feed. The firing rate was about half that of the Thompson, firing 300 to 400 rounds per minute, which allowed the individual soldier to stay “in action” longer.

Combined with the lighter weight of the weapon (eight pounds as compared to the Thompson’s 13+ pounds), the GI armed with an M-3 Grease Gun could carry more ammo and stay in the fight longer that one carrying the venerable M-1928 A1.

In combat, the GIs laughed at the ugly duckling. It lacked the fit and finish of the Tommy Gun, and had none of the “image” that came with the Thompson (which had been used by both gangsters and the FBI in the 1920s and 30s). But when the chips were down, the “Greaser” did its job. Dirt didn’t bother it (except that pesky magazine), it was short and handy, and threw enough of the man-stopping .45 ACP rounds that it could help decide a fire fight.

As one GI said, “I hated that gun when they gave it to me. It wasn’t as sharp looking as my Thompson, and looked like a leftover from the parts locker. But when I needed it, that gun never let me down. I didn’t clean it in combat—I just loaded it and drug it through the mud … and it kept shooting.”

In 1945, the Guide Lamp factory manufactured a simplified M-3 A1 sub-machine gun before production contracts were canceled with the end of the war. A total of 15,000+ were produced, but few saw combat in World War II. During the Korean conflict, the Ithaca Gun Company in Ithaca, New York, produced another 33,000 complete M-3 A1 guns, as well as manufactured thousands of parts for the repair and rebuilding of existing M-3 and M-3 A1 weapons.

The Army originally intended this weapon to be a disposable one—repair parts were not initially ordered or even in the supply system until the end of World War II. The plan, if it broke, was simple: drop it and pick up another. The majority of the failures in combat with this simple gun were related to the magazine, which remained an issue for its entire military career.

The 9mm conversion kit was not widely used, and it is estimated that approximately 1,000 kits were produced by the Rock Island Arsenal and by Buffalo Arms, as well as another 1,000 completed weapons produced by Guide Lamp. The kit consisted of a 9mm barrel, a revised bolt, and a magazine adapter that would permit the use of Commonwealth Stenmagazines. Another variant was produced upon request for OSS use that fitted a silencer to the original barrel. These weapons were built with sound suppressor components produced by High Standard on a Bell Labs design.

However, like many weapons of this era, the M-3 lasted longer in service than anyone thought it would. The Russian Army was provided with a large quantity as part of the U.S. Lend-Lease aid program, but the lack of ammunition left most of them in storage for most of their life. A copy (in 9mm) was produced for the Argentine Army through the 1970s, and was in service long after that time. Several units in the first Gulf War reported for duty with the M-3 or M-3 A1 “Greaser” as an individual-protection weapon for tank-recovery vehicle crews.

A DoD inventory in 1996 showed that more than 1,000 still remained in the depots. Unfortunately for the historical community, few of these have seen the light of day, and examples of the M-3 are seldom seen outside of museums.

The M-3 Grease Gun filled its intended role as an inexpensive, reliable weapon in a wartime economy. It used existing technologies and production methods in new ways to solve a problem and fill a need. While never as popular with the troops as its predecessor, it served the American GI and others around the world for 50 years, and serves as an example of what can be done when there is a need.

In April 1917, America’s armed forces were barely ready for a border skirmish with Mexican revolutionaries and bandits, much less the full-on slaughterhouse of the First World War. American small arms were excellent with the glaring exception of machine guns, of which the U.S. Army had very few. American military leaders had not yet learned the brutal lesson of the Great War for a new century: that automatic arms dominated the battlefield.

U.S. troops on the Mexican border with the Maxim Machine Gun, Caliber .30, Model of 1904. This was the first rifle-caliber heavy machine gun in U.S. Army service, however none of these guns were used by the AEF in France.

Just 18 months later, the situation had changed dramatically. At the end of World War I, American troops fielded the most complete and powerful set of infantry weapons the world had ever seen. By brave application of the force of arms coupled with our national design and manufacturing ingenuity, the United States transformed from a lesser Allied nation to an international superpower and world leader.

A wartime illustration depicting U.S. troops manning what looks like a cross between a British Vickers and an American Browning M1917 machine gun.

Here are a few of the machine guns in use by the American Expeditionary Force (AEF) in France:

The French “Fusil Mitrailleur Modele 1915 CSRG”, or Automatic Rifle, Model 1915 (Chauchat). Regardless of its official title, American troops called the less-than-reliable Chauchat many names that cannot be repeated here. The most widely manufactured automatic arm of World War I, the Chauchat was a good early concept for an automatic rifle, but quite poorly produced. The AEF used the Chauchat in large numbers, chambered in its original French 8 mm Lebel. Subsequent attempts to chamber the Chauchat in the U.S. .30-‘06 cartridge ended in disaster, with the guns essentially unusable and quickly withdrawn.

U.S. troops training with the French designed and built “Automatic Rifle, Model 1915 (Chauchat).” Widely despised by American troops for its shoddy construction and subsequent unreliability, the “damned, jammed Chauchat” still served American troops throughout the battles of 1918. Three American Chauchat gunners earned the Medal of Honor.

The French Hotchkiss M1914 Machine Gun served as the AEF’s primary heavy machine gun until the Browning M1917 machine gun became available later in 1918. The 8 mm Hotchkiss proved to be accurate, reliable and adaptable. It was initially fed with 24-round metal strips, and later in 1917 an articulated metal belt was adopted. Hotchkiss machine guns were widely used in the burgeoning anti-aircraft role, and were also installed in many of the FT-17 tanks that were operated by the American Tank Corps.

The most common heavy machine gun in the hands of the AEF was the French 8 mm M1914 Hotchkiss. Sturdy, heavy, reliable and adaptable, about 7,000 of them served with American forces in France.

British Automatic Arms: Two American divisions were attached to the British in the Somme area, and thus spent some time using the .303 cal. Lewis Light Machine Gun, the Hotchkiss Portative light machine gun, and the Vickers Machine Gun in combat during 1918.

Marines training at Quantico with a Lewis Gun during 1916. While the Lewis was very popular with the USMC, the Marines’ Lewis guns were taken away and replaced with the less reliable French Chauchat machine rifle.

Browning M1917 .30 cal. Machine Gun: About 1,200 of John Browning’s heavy water-cooled machine guns saw service during the last three months of World War I. Very quickly, the M1917’s reliability, accuracy and rate of fire became legendary. The water-cooled M1917 served with U.S. forces in World War I, between the wars, throughout World War II, the Korean War, until phased out of U.S. service in the late 1950s.

Val Browning (son of the designer, John Moses Browning) test fires one of his father’s incredible designs, the Browning M1917 .30 cal. heavy machine gun. Fielded late in the war, the M1917 nonetheless established a reputation for reliability and accuracy.

These men of the 80th Infantry Division were armed with a Browning M1917 machine gun, which featured a “beer can” flash hider.

Browning Automatic Rifle: John Browning’s genius automatic rifle design only saw service very late in the war, beginning in about mid-September 1918. Regardless, the BAR quickly proved to be the finest light automatic of the war, impressing enemies and allies alike. First World War BAR gunners were initially provided with a special cup-like device, mounted on their cartridge belts, designed to hold the butt of the BAR stock firmly in place and enable the concept of “walking fire.” The walking fire concept proved to be completely impractical, but the BAR went on to be legendary, serving with U.S. forces even into the Vietnam War.

The outstanding Browning Automatic Rifle flanked by the French-built M1915 Chauchat in 8 mm Lebel (right) and the “American M1918 Chauchat” in .30-‘06 (left). Unfortunately for U.S. troops, the BAR did not reach frontline troops until the very end of the war, and the M1918 Chauchat in U.S. .30 cal. was almost completely non-functional.

Val Browning tries out a M1918 Browning Automatic Rifle in the “walking fire” style in France during 1918.