Category: All About Guns

America’s enduring Model 1911 .45-cal., semi-automatic pistol remains a landmark sidearm more than a century later. Yet how it was introduced to service and typically carried by soldiers, sailors and marines before World War I remains lesser known.

Self-loading handguns became possible with the French invention of smokeless powder in 1884. Two blue-blooded Austrians, Karl Salvator and George von Dormus, patented their pistol in 1891, which held five rounds of proprietary 8 mm ammunition. It failed to find a market, but an improved version by another Austrian, Josef Laumann, entered production at Steyr the next year.

Thereafter, customer interest grew fairly quickly. In 1894, Hugo Borchardt’s C-93 in 7.65×25 mm attracted buyers with its eight-round detachable magazine, followed by Paul Mauser’s iconic “Broomhandle” in 1896, with ten rounds of 7.63×25 mm carried internally.

For the most part, the decade produced largely dead-end designs from Germany, Austria, Belgium and Spain, until Georg Luger arose. His 9 mm chambered P08 (for 1908) was first accepted by Switzerland in 1900, then by Germany along with many other nations.

In the United States, John M. Browning filed his first pistol patent in 1895, leading to the Belgian firm Fabrique Nationale’s hammerless .32-cal. Model 1899, followed by the enormously popular Model 1900 in .380 ACP. Retaining the detachable magazine but with grip and thumb safeties, the Model 1903 was produced in .32 and .380. Between them the Models 1900 and 1903 probably sold more than 850,000 units.

Placed in context, the .45 ACP emerged at the end of more than a decade of sidearm development. The M1892 was the first U.S. double-action revolver with a swing-out cylinder, chambered in the anemic .38 Long Colt. Adverse reports from the Philippine Insurrection, fought from 1899 to 1902, led to the M1909 in .45 Long Colt. A succession of variants emerged, with the stocks of the M1903 narrowed to provide an improved grip.

The stage for the M1911‘s development and adoption was set in 1907, when an Army board decided to replace its standard-issued revolver. Colt and Browning had collaborated on a nascent .41-cal. pistol round, but the Army’s Thompson-LaGarde ballistics tests of 1904 influenced development. Consequently, Browning modified the new cartridge as with a 200-grain, .45-cal. bullet, launched at 900 f.p.s. The round appeared in the prototype Colt Model 1905, and after extensive testing by military and industry representatives, the final combination yielded the classic .45 ACP cartridge, with its 230-grain projectile launched at upwards of 850 f.p.s.

Army Ordnance concluded, “After mature deliberation, the Board finds that a bullet which will have the shock effect and stopping power at short ranges necessary for a military pistol or revolver should have a calibre not less than .45.”

Several aspirants entered pistols chambered for the new cartridge, and after elimination of other designs (including semi-auto revolvers), Colt’s and the Savage M1907 entries contended for the government contract. In the end, the final selection trial was not even close. The Colt ran flawlessly, while the Savage sustained dozens of stoppages.

As noted by American Rifleman’s predecessor, the April 1911 issue of Arms and the Man, declared, “the good old revolver became obsolete, and in its stead there was marked for the holsters of this Nation’s defenders the .45 Colt’s automatic; the latest, the most deadly, the finest and the best hand arm which had yet to be produced by man.”

Late in the final design process, the Army requested a thumb safety, which Browning added shortly before production began. The service requirement for a grip safety already was met, as Browning’s M1903 set the pattern for the military. Thus, the M1911 .45-cal. pistol evolved in a golden era of small arms design.

The Model of 1911 was adopted that March, with 21,000 delivered through December, including Navy and Marine Corps orders. Aside from the semi-automatic Mauser and Luger pistols, in the same period of time most nations were still introducing bolt-action service rifle designs. Britain adopted the Lee-Enfield rifle in 1895 and Germany’s Mauser designed Gewehr 98 came three years later. America had only adopted the classic Springfield M1903 rifle eight year prior.

Troops quickly noted the weight difference. The M1892 revolver weighed barely 2 lbs., while the Colt M1911 weighed nearly 2.5 lbs. with empty magazine, which may partly account for the decision to mate the pistol and holster to the sturdy 1910 pattern duty belt. The Colt was carried in the M1912 holster, with a twin magazine pouch. Accessories were adaptable to the standard belt, which was frequently updated. Usually it was made of webbing or canvas duck, featuring rows of three vertical grommets to accept hooked hardware for holsters, canteens, and bayonets. Most of these pistols were produced with a lanyard loop in the butt, mainly for cavalry use.

In a 1913 article, Ensign C.E. Van Hook, an influential Navy instructor noted, “Eternal vigilance is the only price of safety.” Yet he commended the semi-automatic, partly because: “The trigger pull always remains the same, which is a decided advantage over the disconcerting double action of the .38-cal., and makes it a great deal more accurate for rapid firing.” As issued, the Colt M1911’s trigger usually lets off at 6 to 7.5 lbs. Van Hook also noted “(the pistol) may be loaded with greater ease and rapidity. This takes into consideration the fact that under service conditions a number of extra clips, loaded and ready for instant use, would be carried in a specially designed belt.”

The M1911’s large frame caused problems for many users accustomed to the revolver’s smaller size. The Naval Institute Proceedings article observed, “One very simple way of overcoming most easily this short finger contingency lies in using the middle finger as the trigger finger. By using the middle finger, even without any previous practice, the shooter can get a better and freer purchase on the trigger.

Moreover, the middle finger is normally stronger than the index finger thus enabling the shooter to execute a smoother trigger squeeze. Let us assume that you are using the middle finger to “pull” the trigger. You will find it convenient to place the index finger either alongside the slide or on the receiver, depending on your own finger length.

However, the Army Ordnance manual of 1912 noted, “The trigger should be pulled with the forefinger. If the trigger is pulled with the second finger, the forefinger extending along the side of the receiver is apt to press against the projecting pin of the slide stop and cause a jam when the slide recoils. Additionally, some military teams allowed carving finger grooves in the 1911’s stocks for improved control, especially in rapid fire.

In 1926, the Army accepted modifications in form of the M1911A1, with an arched mainspring housing, a shorter trigger and frame indents behind the trigger. The annoying problem of hammer bite was largely eliminated with a shorter hammer spur and longer grip safety. However, many shooters preferred the original flat mainspring housing for greater purchase on the grip, and sometimes could retro-fit the original housing.

The Ordnance Departed listed muzzle velocity of 230-grain bullet at 802 f.p.s., penetrating 6″ of pine at 25 yards. Remarkably, trajectory was charted to 250 yards. The maximum ordinate was 4.29 feet (51.5″) at 126 yards. “The trajectory is very flat up to 75 yards, at which range the pistol is accurate.” (As a side note: Joe Foss’ Air Force Reserve M1911A1, manufactured in 1944, grouped with 2″ extreme spread at 20 yards, but 8″ high.)

Reporting on range tests the manual said, “This pistol has been fired 21 times in 12 seconds, beginning with the pistol empty and loaded magazines on a table. Firing at 25 yards at a target 6 feet by 2 feet under the same conditions, 21 shots were fired in 28 seconds, making 21 hits with a mean radius of 5.85″.” (Hatcher’s Notebook, page 421, described mean radius as the average distance of all shots from the center of a group; mean radius usually measured one-third of a group’s diameter.)

When action seemed imminent, the Army’s 1912 Description of the Automatic Pistol suggested topping off to eight rounds. The method seems peculiar today: with the magazine removed, lock the slide open and insert a cartridge in the chamber. Trip the slide release, thus seating the round. Then a full-up seven-round magazine was inserted. It’s unknown how often loose rounds were available in the field. A far more likely technique was chambering the first round off one magazine and reloading with a full mag to bring the total to eight.

Addressing safety features: “The automatic grip safety at all times locks the trigger unless the handle is grimly grasped and the grip safety pressed in. The pistol is in addition provided with a safety lock by which the closed slide and the cocked hammer can be at will positively locked into position.” Decades later, speaking of the grip and thumb safeties, former Marine Lieutenant Colonel Jeff Cooper insisted, “If the 1911 were any safer it would be almost useless as a weapon.”

Decades of gun lore hold that the services originally carried the M1911 “cocked and locked,” or in today’s parlance, condition one. Presumably the policy changed after some negligent discharges. Allegedly, Lt. George Patton fancied himself a gunsmith and “improved” his automatic by filing the sear with exciting consequences, hence his devotion to revolvers. However, documentation indicates otherwise.

Contemporary sources heavily indicate that cocked and locked was only advocated facing imminent threat. The Ordnance manual noted that with a round chambered, “The slide and hammer being thus positively locked, the pistol may be carried safely at full cock, and it is only necessary to press down the safety lock (which is located within easy reach of the thumb) when raising the pistol to the firing position.”

However, Ordnance also advised, “Do not carry the pistol in the holster with the hammer cocked and safety lock on, except in an emergency. If the pistol is so carried in the holster, cocked and safety lock on, the butt of the pistol should be rotated away from the body when withdrawing the pistol from the holster in order to avoid displacing the safety lock.”

The problem, of course, is that it’s impossible to schedule an emergency. It was especially true in combat zones where enemy infiltrators or trench raiders might appear suddenly, at close range, often in darkness. Other concerns involved guard duty at a base entrance or building where emergencies seldom arose but the potential still existed.

The cavalry’s 1940 pistol field manual addressed modes of carry (page 19): “In campaign, when early use of the pistol is not foreseen, it should be carried with a fully loaded magazine in the socket, chamber empty, hammer down. When early use of the pistol is probable, it should be carried loaded and locked in the holster or hand. In campaign, extra magazines should be carried fully loaded.”

More than a century before the bane of today’s gun writers, the U.S. Government initiated the semantic heresy of referring to a pistol as a “revolver” and a magazine as a “clip.” An interwar Navy instruction advised, “Take the revolver in your right hand and the clip in your left. Show him how to insert the clip, trip the slide, inject the first round into the chamber, etc.”

The director of cavalry stipulated that mounted pistol exercises “will be carried on during the entire year.” Furthermore, drill would involve simulated firing at different objects at all gaits from walk to gallop. Most targets were positioned at five to seven yards so troopers were required to engage right and left front; right and left flank; and right rear, the left hand of course holding the reins.

Anyone who has watched a SASS mounted event knows the common cavalry technique: leaning toward a front-aspect target while half rising in the stirrups, thrusting the pistol forward in the most direct line, wrist rigid, and forcing the right elbow to the left in vertical plane with wrist and shoulder. Trigger control was to be coordinated with start of the thrust, “He selects his target, fixes his eyes upon it with concentrated effort, catches sight of the target over his barrel, and squeezes his trigger with steadiness and precision.”

Live-fire drills showed the importance of follow through. Most misses were attributed to troopers’ failure to keep eyes on the target until after the shot was fired. Concentration was paramount. Perhaps understandably in the midst of a cavalry charge, riders tended to look for the next target an instant before the round went. At all times troopers were strongly advised to keep the muzzle well ahead of the horse’s face for obvious reasons.

The manual devoted two pages to training horses not only around gunfire, but getting them accustomed to unusual sizes, shapes, and colors. Long experience showed the wisdom of gradual exposure to unfamiliar objects and conditions, most often in groups rather than individually. Blanks and live fire were introduced as the mounts grew in confidence. Dismounted cavalry courses were fired at 15 to 50 yards, frequently walking toward pop-up targets. Various dates have been cited for the M1911’s combat debut, as early as 1913, but the most likely seems to be Marine Corps use in Haiti from 1915 onward.

In whole or in part, at least thirteen Army men earned the Medal of Honor with M1911s in World War I. Two Marines used Browning products twelve months after the armistice as Lt. Herman H. Hanneken and Cpl. William R. Button wielded both the M1911 and BAR, respectively, in their Medal action against Haitian rebels. Since then, the M1911 has appeared in well over 120 theatrical movies through 2021, plus hundreds of television movies and episodes. That compilation excludes Commanders, Series 70/80s, other manufacturers, blank-firing copies, and portrayals in cartoons and video games.

In the 1969 film The Wild Bunch, a German advisor to the Mexican general notes that the Americans carry handguns “that may not be acquired legally.” In fact, the Colt Commercial “Government” models were marketed in 1912, with an initial run of 1,899 pistols. The civilian market has only expanded in more than a century. Some 110 years later, the M1911 repeatedly finishes atop reader polls as “the most iconic American handgun.” Last year, Shooting Illustrated placed the M1911 ahead of the CZ 75 and Beretta 92, and even the classic 1873 Single Action Army. The fanfare of the M1911 shows no sign of abating.

To understand firearm development, it is necessary to have some knowledge of the economy during their progress. The Civil War brought about a great increase in economic opportunities—hence industrialization—to the Union. Manufacturing business grew at a phenomenal rate. The war created a huge market for firearms and fueled the development of their technology. While the waging of war created the demand, it was the Reconstruction period after the war that brought about a maturation of that booming economy. The U.S. military—primarily the army at that time—needed better firearms with which to serve the country.

Single-shot and repeating rifles fed by cartridges that were ignited with a primer pressed into the center of the rear of the case replaced cap-and-ball muzzleloaders and rimfire-primed cartridges. Revolvers—which had progressed nicely into the cap-and-ball technology—began seeing their own cartridge development to centerfire-primed rounds. They were very popular with the cavalry because they could be operated with one hand and offered as many as six shots before requiring a reload.

Colt rather quickly came out with a Benet-primed .44 Colt cartridge for its Richards-Mason conversion of the 1860 Army. The actual diameter of the heeled, outside-lubricated bullet was .451″to .454″, and it featured a 225-gr., conical lead bullet in front of 23 grains of FFg blackpowder for a velocity of 640 f.p.s. and 207 ft.-lbs. of energy. Charles B. Richards, an engineer at Colt, and William Mason, a gunsmith who came to Colt from Remington in 1866, worked together on the .44 Colt cartridge, which was introduced in 1871.

The Richards-Mason conversion was a stopgap measure as the company retooled and set up to manufacture what would become the Colt Model 1871-72 Open Top revolver. This revolver was chambered in the more powerful .44 Henry Rimfire cartridge, a major step up in power from the .44 Colt. It was capable of kicking a 200-gr. conical ball bullet out at 1,125 f.p.s. with 568 ft.-lbs. of energy, though these numbers are probably from a rifle.

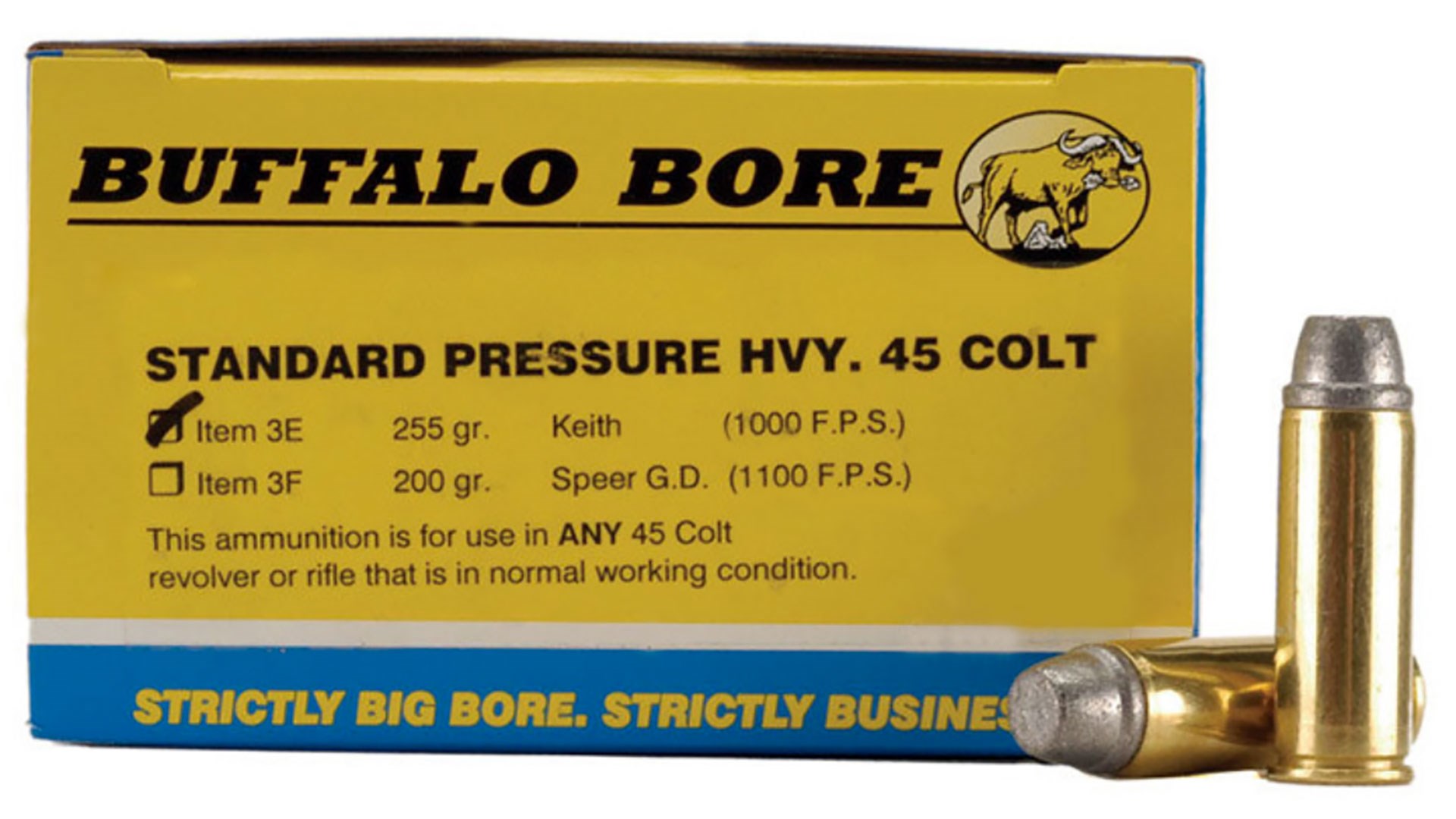

Buffalo Bore .45 Colt available today loaded with a 255 gr. lead bullet.

Buffalo Bore .45 Colt available today loaded with a 255 gr. lead bullet.

Nonetheless, the army bought several thousand of them for its cavalrymen during the revolver’s two-year production run. Three things became very clear. The army wanted a more powerful revolver. It did not want outside-lubricated bullets that pick up dirt and grit from the field. And a revolver tough enough to stand up to these rigors must have an enclosed window for the cylinder, what we now refer to as a solid frame.

Richards and Mason began developing a new revolver and teamed up with ammunition engineers at Remington to manufacture the cartridges. Both the revolver—the 1873 Colt Single Action Army(SAA)—and its cartridge, the .45 Colt, would become iconic in the annals of firearm development. The .45 Colt retains the bullet diameter of its .44 Colt predecessor at .452″ – .454″ but kicks the weight of the bullet up to 255 grains.

After playing with loads with bullets as light as 225 grains and powder weights from 28 to 40 grains, they settled on the 255-gr. bullet in front of 40 grains of FFg blackpowder for 840 f.p.s. with about 400-ft.-lbs. of wallop out of a revolver. Production of ammo and revolver began in 1873. The army quickly saw the improvement of both revolver and load, as did civilians, and the Colt .45, as it became commonly called, generated a great reputation as a man-stopper.

All of the preceding did not occur in a vacuum. Smith & Wesson had been hard at work on its No. 3 revolver in .45 caliber. In fact, the army adopted the No. 3 in 1870 chambered in .44 Smith & Wesson American. But the brass wanted more power. Major George W. Schofield had an engineering improvement to the Model 3. Instead of mounting the spring-loaded barrel latch on the barrel, he reversed it and mounted the latch on the frame.

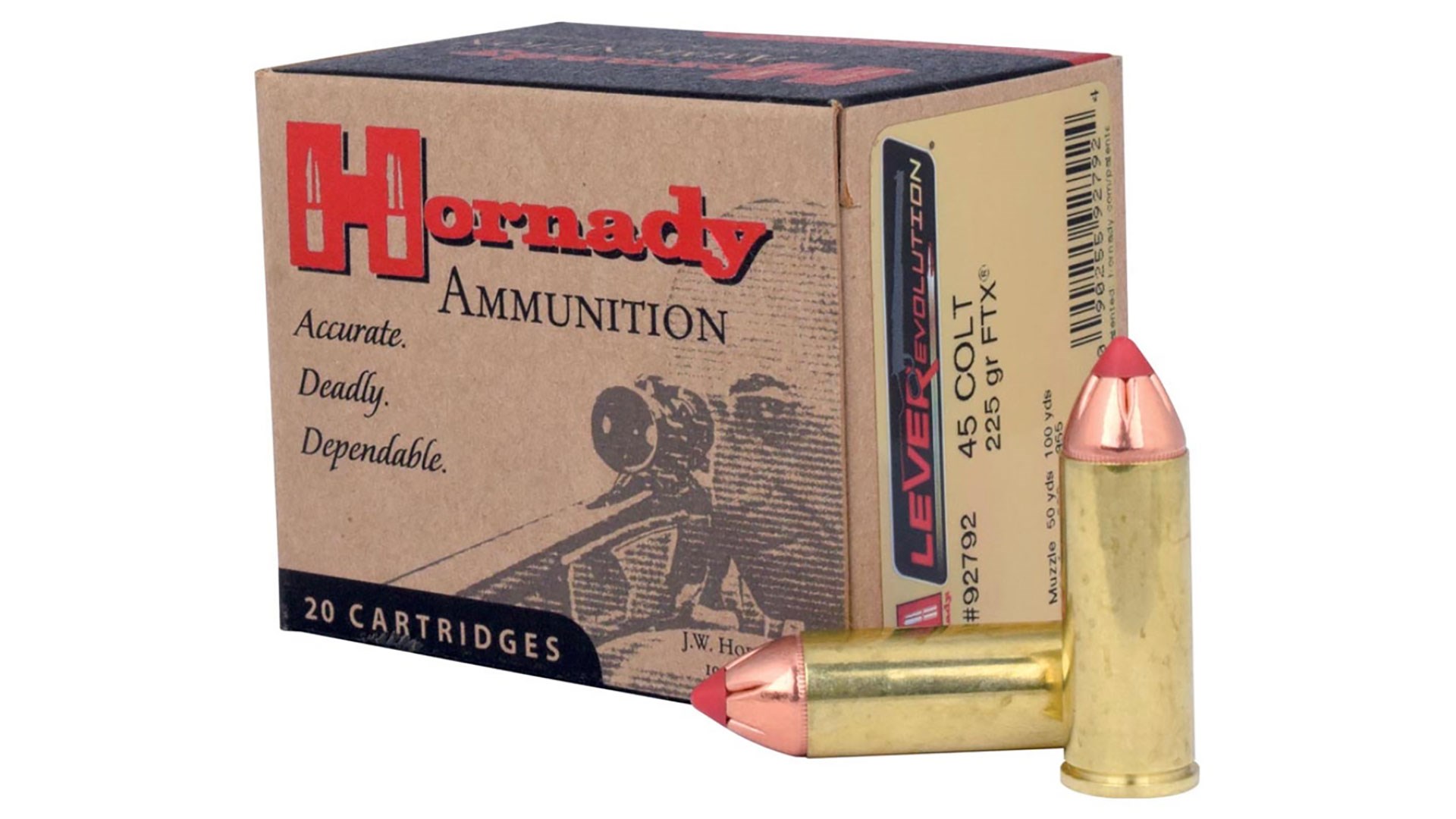

Hornady .45 Colt cartridges loaded with a .255 gr. FTX bullet.

Hornady .45 Colt cartridges loaded with a .255 gr. FTX bullet.

The army specified that the revolver would chamber the .45 Colt cartridge, but the Smith & Wesson revolver’s cylinder was too short do it was chambered in a shorter .45 Smith & Wesson—often referred to as the .45 Schofield, adopted in 1875. The Smith & Wesson cartridge would function in the Colt SAA but not vice-versa. Army quartermasters had headaches trying to sort out ammo for each revolver. Frankfort Arsenal, which supplied nearly all the ammo for the Army, simply ceased loading the .45 Colt and supplied the troops with .45 S&W cartridges.

Somewhere in all of this the .45 Colt nomenclature was colloquially changed to “.45 Long Colt” to differentiate it from the shorter S&W cartridge. From bank heists to battlefields, train robbers to shopkeepers, the .45 Colt and the SAA was king. Sure, there were plenty of those finely made Smith & Wessons, but out on the frontier far from gunsmiths, people counted on the robustness of the SAA and its man-or-beast-busting .45-cal. cartridge.

They must have done something right because, 147 years later, the cartridge continues to be loaded. Other than in wartime, there hasn’t been a hitch in production of the .45 Colt cartridge. The military could not leave well enough alone. Some 21 years after the introduction of the Colt SAA and its .45-caliber round, the military adopted the Model 1892 Colt double-action revolver chambered in a .38 Long Colt cartridge developed in 1875, featuring a 150-gr. lead, round-nose bullet launched by blackpowder at 708 f.p.s. with a measly 157 ft.-lbs. of energy out of a 6″ barreled revolver.

Sometime later, a smokeless powder load sent a 148-gr. bullet downrange at 750 f.p.s. and 185 ft.-lbs. of energy. Some bad experiences in the Philippines during the Philippine–American War of 1899–1902 against Moro juramentados tribesmen had the army scrambling for anything that could fire .45 Colt cartridges. This led to Colt developing the M1909 round , identical in load to the original .45 Colt round but with a larger rim to accommodate the star-like extractor/ejector of the New Service double-action revolver.

The author’s Ruger Blackhawk chambered for .45 Colt.

The author’s Ruger Blackhawk chambered for .45 Colt.

M1909 ammunition will not work in single-action revolvers chambered in .45 Colt because the rim diameter interferes with adjoining cartridges. Even as semi-auto pistols began emerging, the .45 Colt has remained a steady-selling cartridge. Two reasons for that is the reliability and longevity of the SAA revolver and the fact is that it plain works.

Whether dealing with desperados, deer or even black bears, in the hands of a decent shot, a man armed with a .45 Colt will go home to his family or bring home the game. In the mid-1950s, a Utah-based gunsmith and experimenter named Dick Casull began exploring the limits of what a .45-cal. handgun could produce. He started with blackpowder-framed Colt SAAs, re-heat treating the frames and converting them to five-shot cylinders.

In 1959 he introduced the .454 Casull cartridge featuring a case 1.383″ long—some .098″ longer than a .45 Colt case—and a thicker web in the head of the case that Casull claimed to get more than 1,900 f.p.s. with a 250-gr. bullet. The power guys went nuts over this, but it would take almost 25 more years before this cartridge would be commercially loaded and have a factory manufacture a revolver that could handle it. In the meantime, Ruger chambered its tough Blackhawk revolver in .45 Colt, as did Thompson/Center in its equally solid Contender single-shot pistol.

Power guys ignored the loading manuals of the day and began dropping huge charges of slow-burning powders into .45 Colt cases to see what they could get away with. Now called T-Rex loads by the brethren, many loading manuals gave loads for these guns expressly and specifically. As for me, if I want an extremely powerful revolver—which I do not anymore—I would choose a cartridge expressly made for those tasks. I like the .45 Colt for what it is: a moderately powerful handgun cartridge that does anything I might ask from a handgun.

A view from the muzzle end of the author’s Ruger Blackhawk chambered for .45 Colt.

A view from the muzzle end of the author’s Ruger Blackhawk chambered for .45 Colt.

As with all my revolvers, save my J-frame Smiths, I prefer to cast hard semi-wadcutters at some 258 grains in my .45-cal. with 9.0 grains of Alliant Unique powder. In my 4 5/8″ Ruger, it gives me about 912 f.p.s. with 476 ft.-lbs. of muzzle thump. If I need more thump, I’ll choose a rifle—too many years of shooting those big bruisers has left me with some arthritis in my hands.

All the major factories load the .45 Colt cartridge today; one of the smaller manufacturers—Garrett, in Texas, loads +P .45 Colt rounds that are expressly for the Rugers. But there are plenty of JHP and SP loads available—outside of the pandemic-induced ammo shortage. There are even relatively soft-recoiling loads for cowboy action shooters. It is the cowboy action shooters that brought another firearm into the .45 Colt fold—rifles.

When the cartridge was introduced, the small diameter and thin rim of the .45 Colt cartridge, along with the straight-walled case, would not feed or extract reliably in the lever-action rifles of the day. Too, it was fueled with blackpowder, which leaves a rather heavy residue. A straight-walled case would often hang up because of that following, especially if the residue was exposed to dampness.

Today, however, Winchester, Uberti, Henry and Cimarron have produced replica lever actions chambered in the big 45. Smokeless powders, some engineering tweaks and the clientele who keep their competition guns clean has largely neutered the old attitude toward .45 Colt lever actions. Continuously produced for nearly 150 years, both in ammo and guns, the .45 Colt remains a capable cartridge for field use or even self-defense. I know several fellows who regularly have a single-action revolver on their belt on a daily basis, and that revolver is a .45 Colt.

By John B. Snow Photographs by Bill Buckley

In celebration of its 100th anniversary, Griffin & Howe decided to build a small number of rifles worthy of the occasion. As you can see in the photographs, they are stunners—but there’s more to these beauties than meets the eye. These inspired creations commemorate not only the founding of the illustrious gun company but also its special connection to Townsend Whelen and Outdoor Life.

That’s a lot to take in, so allow me to dial the clock back to the early decades of the 20th century.

Whelen—most often referred to as Colonel Townsend Whelen— was a career Army officer who loved hunting the wilderness and had a deep appreciation of fine rifles, ballistic innovation, and the art of precision marksmanship. He communicated these passions with a clear, straightforward writing style that earned him a wide following and eventually the unofficial title of dean of the outdoor writers.

His most enduring legacies are the statement that only accurate rifles are interesting — which was the title of a story he wrote for American Rifleman in 1957—and the cartridge that bears his name: the .35 Whelen.

Little surprise that a man of his (ahem) caliber was one of the first shooting editors of Outdoor Life, a position he held for many years before passing the mantle to Jack O’Connor.

By way of context, since 1898, the year of OL’s founding (we’re celebrating our 125th anniversary this year), we’ve only had five shooting editors. In order, they are: Charles Askins Sr., Col. Townsend Whelen, Jack O’Connor, Jim Carmichel, and your humble correspondent.

THE GENESIS OF GRIFFIN & HOWE

Whelen started writing for Outdoor Life around 1906 and contributed to the publication well into the 1930s. At some point during the 1910s, he caught wind of a talented stock maker, Seymour Griffin, who had built a reputation for turning homely government-issue Springfield 1903s into lovely sporting pieces.

Whelen was already an influential force in the development of sporting and military arms and munitions by that time. His day job was director of research and development at Springfield Armory and commanding officer of Frankford Arsenal.

In 1921, Whelen met James Howe, a gunmaker and foreman of the Frankford Arsenal machine shop. Together they started working on a new family of cartridges based on a .30/06 necked up to different diameters, including .400, .375, and .35. Of these “Whelen” cartridges, only the .35 Whelen made significant inroads with the shooting public—and even so, it remained a wildcat from 1922 until 1988, when Remington finally offered it as a commercial load.

Whelen introduced Griffin and Howe and urged them to go into business together. Acting as an official advisor, he helped them procure financing.

Griffin & Howe, a sporting goods store and custom gunmaker, opened on June 1, 1923, at 234 East 29th Street in New York City. Though his name isn’t on the company’s trademark, Whelen is rightfully acknowledged as one of Griffin & Howe’s founders.

The business quickly grew, and Griffin & Howe developed a worldwide reputation for making fine hunting rifles; it soon became one of the premier sources for hunters and sportsmen looking to get outfitted for adventure. Its clientele included Ernest Hemingway, Robert Ruark, Gary Cooper, Clark Gable, Bing Crosby, President Dwight Eisenhower, and other luminaries.

Over the past 100 years, the company has had its share of ups and downs but continues to endure. Today, its home base is Hudson Farms in Andover, New Jersey, and it is under the directorship of company president and CEO Steven Polanish.

A PERFECT PAIR

About eight years ago, Griffin & Howe expanded its rifle line with the introduction of the Long-Range Precision Rifle and since then has added the Highlander and All-American models.

The rifles here are Highlanders, which are built on control-round feed actions produced by Defiance Machine and have a classic three-position safety mounted on the bolt shroud.

Both rifles are chambered in .35 Whelen, naturally, and blend traditional design elements with interesting innovation.

Because of Whelen’s role in getting Griffin & Howe off the ground and his position at Outdoor Life, OL and G&H have always enjoyed a strong connection and friendship. It’s a relationship that’s lasted throughout the decades and is the reason I was able to get a first look at these special guns.

UNIQUE SIGHTS

The carbon-fiber barrels, which are made by Proof Research, may have caught your eye. They were constructed to accommodate an island rear sight, which, to the best of my knowledge, has never been done on a carbon-fiber barrel before, and certainly never as a standard offering.

These sights are a thing of beauty. They’ve been regulated to hit spot-on at 100 yards and have a single leaf that flips up for 200- yard shots.

While I spent a lot of time shooting these rifles for accuracy off the bench with the Swarovski Z8i 1-8x24s they came with, I couldn’t wait to pull the optics off—both rifles feature Griffin & Howe’s proprietary quick-detach scope mounts—and run them with open sights.

I was able to easily ring the 10-inch gong at 100 yards with every shot. The bead on the front post is protected by a sturdy shroud and settled nicely into the notch of the shallow “V” formed by the rear sight. A vertical white line running up the middle of the

rear sight helps the shooter center the front bead precisely in the notch.

When I moved to 200 yards, it took me a couple shots to spot my bullet impact—I was hitting a bit high—but I made the adjustment and went two for three at that distance.

In my mind’s eye I was no longer at a shooting range, but rather I was hunting in East Africa back in the 1950s, putting down a Thomson’s gazelle for camp meat or stalking close to a kudu bull crowned with horns spiraling toward the heavens.

Not many rifles can transport a shooter that way, but these do. A rifle bearing the Griffin & Howe name, chambered in the Whelen, and topped with nothing more than crisp and effective open sights, was something to aspire to back in the day. It still is.

WONDERFUL WOOD

The rifle with the composite stock is built for hard work and is pleasant enough to look at for a gun of that type, but it pales in comparison to the glorious wood on the other rifle.

The French walnut that Polanish selected—he purchased both of these rifles, which have serial numbers GH35000 and GH35001— is a great canvas on which to showcase the stock maker’s art.

The stock maker in question is Dan Rossiter, the shop foreman at Griffin & Howe and a member of the prestigious American Custom Gunmakers Guild.

The hand-cut checkering is perfect, with the diamonds on the fore-end and grip in line with the border, as it is supposed to be.

The raised Monte Carlo cheek piece, with its negative comb, is outlined with a sharp and attractive shadow line. The ebony tip on the fore-end and leather recoil pad bookend the highly figured wood, completing the elegant execution of the stock.

The grip was cut with a slight palm swell. It isn’t enough to distract from the rifle’s classic lines, but it is a nice modern ergonomic enhancement that shows how the old and new can coexist in a modern hunting rifle.

FLAWLESS FIT AND FINISH

I handed the rifle at one point to a friend of mine in his early 30s who is an accomplished long-range shooter and knows his way around modern precision rifles—and, in fact, builds them for a living. But he’d never seen a rifle like this and was puzzled by the seamless fit between the stock and barreled action.

He asked whether that was normal, and it drove home how mating a stock and action this way has become a relic of another era. Free-floating barrels isn’t new—Whelen was advocating it decades ago—but it has become so ubiquitous that the old-school technique of tight stock fitting has all but disappeared.

That level of fit and finish is evident everywhere else on the rifle, too. The inletting around the bottom metal, the ejection port, the grip cap, the tang—all of it is done to less than a hair’s width of tolerance.

One thing worth mentioning is that the Torx-head guard screws are going to be replaced with proper slot-head fasteners soon. In the hurry to get the rifle ready for my hunt, that small corner was cut.

NEXT LEVEL ENGRAVING

The wood stock and carbon-fiber barrel create the initial visual impression of the rifle, but as soon as you get close to it, what really stands out is the adornment on the metal.

One of the things that’s so appealing about this rifle is that it is a family affair. Chris Rossiter—brother of stock maker and shop foreman Dan—is also a member of the ACGG and did the engraving.

All told, Chris put 198 hours of meticulous handwork into the rifle using hammers and fine-pointed chisels that, depending on their shape and local custom, are known as burins, gravers, tints, or spitstickers. Every metal surface on the Highlander has some

engraving and each is delightful to behold.

The engraving on the magazine floorplate is particularly intricate. It features a portrait of a bighorn sheep—which has been part of Griffin & Howe’s logo since day one—surrounded by vines and scrollwork and framed within a border consisting of elegant curving lines.

The vines and pattern of wavy lines are repeated on other sections of the rifle. The deep relief on the right side of the action is simply amazing, though, in fairness, that description applies to all the engraving.

From a personal standpoint, I also greatly admire the lettering on the rifle. The bold “Griffin & Howe” engraved on action is done in a gorgeous font that reflects the art deco aesthetic that was in vogue when the firm was founded in 1923.

Much of the rifle is still in the white, which really shows the engraving to full effect, but some elements have been color case hardened. The scope rings, scope bases, front and rear sights and grip cap got that treatment.

Mixing those colors and textures isn’t exactly traditional, but it does showcase Griffin & Howe’s rifle-building chops in a dramatic fashion.

Of course, no two of these rifles will be the same. Griffin & Howe is making only 10 of the wood and 10 of the composite stocked models, and each will be built according to the customer’s preference. That includes choice of wood, stock dimensions, type of recoil pad, and style and quantity of engraving.

IN THE FIELD

In one of the more audacious moves of my career, I decided to take these Highlanders hunting. The wood stocked Highlander has a base price north of $20,000 and a bit more than that in the engraving, for a total cost of $44,000, give or take. By comparison, the synthetic stocked version is a budget gun at $12,400. I’ve never hunted with a pair of guns as costly, but that didn’t stop me from loading them into the back of my pickup and driving 1,000 miles north from Montana to a remote area near Alberta’s Lesser Slave Lake.

On the drive to camp I picked up Steven Polanish at the airport in Edmonton and we continued on our way to chase bears with John and Jenn Rivet, who own Livin the Dream Productions.

We spent a week in the woods, a thick mixture of poplars, birch, and spruce, watching bears from tree stands and ground blinds during the long northern evenings.

Polanish shot a bear of a lifetime during the hunt—a huge color phase cinnamon bear that squared more than 7½ feet. My bear, a 7-footer, was no slouch either.

It will come as no surprise to anyone who has experience with the .35 Whelen that the rifles and cartridge performed well. Both of our bears were flattened with one shot and hardly moved.

The ammo we used was Barnes factory 180-grain TTSX FBs. The shots in this country aren’t far—anything more than 25 yards would qualify as a poke—so the bullets are carrying nearly every bit of their velocity upon impact. From the wood gun, muzzle velocity averaged 2941 fps, while the barrel on the synthetic gun was

a touch faster at 2961 fps.

Those tough monometal bullets passed through both bears, leaving exit holes that indicated impressive expansion.

The recoil generated by the rifles is a bit more than what you’d get with a .30/06. Shooting 20 or 30 rounds at the range isn’t cumbersome, but with longer range sessions, the kick of the .35s will wear down your shoulder.

That’s the price, however, for a hard-hitting medium-bore cartridge like the Whelen, and that’s why it is an excellent choice for elk and other large game.

A LONGSTANDING LEGACY

With the creation of these rifles, Griffin & Howe has done an impressive job memorializing the milestone of their 100th year and the contributions Townsend Whelen made to their success.

In my own nod to tradition, I’m going to engage in the time-honored practice among gun writers of contrarianism.

Whelen got most things right, but when he said only accurate rifles are interesting, he missed the mark. Jim Carmichel and I discussed this point years ago over martinis, and we agreed that inaccurate rifles are often more interesting because they present

a problem to be solved—and the process of coming up with a solution makes the gun writer’s profession fascinating indeed.

But whether a rifle is interesting hinges on more than if it places bullets in precise clusters, and I think these rifles are proof of that. They are both accurate and capable of leveraging everything the .35 Whelen brings to the party in terms of exterior and terminal ballistics. But, really, that’s not the yardstick by which they should be judged.

They are expressions of the highest form of the traditional gunmaker’s art but executed with nods to modern trends and sensibilities that are surprising and refreshing to see. The blend of old and new contained within the format of barrel, action and stock that is as familiar to riflemen as their reflection in a mirror is a remarkable achievement.

I don’t know if I could change Whelen’s mind on his assertion. We ballistic scribes tend to stick to our guns, literally and figuratively. But if nothing else, he was always forward thinking with respect to rifles and marksmanship and had, dare I say it, a progressive mind when it came to innovation.

I know he would feel humbled and honored if he could hold and shoot these rifles. Despite his remarkable achievements, Whelen was never one to put on airs. And once he got a closer look and could see what went into their crafting, I’d be shocked if he didn’t say to himself, These are…interesting.