Category: All About Guns

The flat shooting and light recoiling 6.5 Creedmoor was introduced by Hornady in 2007.

Based on a 308 Winchester case, the 6.5 mm (.264″) Creedmoor fits inside an AR10/ 308 AR platform and feeds well from AICS style magazines.

The Creedmoor is unique among the current crop of 6.5 cartridges such as the 260 Remington and 6.5×47 Lapua in that match grade factory ammunition is readily available and relatively cheap (Lapua sells factory ammunition for the 6,5×47 Lapua, however, it is more expensive and less frequently encountered). A big plus for newer shooters who don’t reload.

6.5 Creedmoor is a great option for custom bolt action rifles. A rifle chambered in 308 Winchester can simply be re-barreled for the Creedmoor.

All other parts, including the magazine system, will work. Unlike some other 6.5mms, such as the 6.5×284 Norma, reported barrel life is relatively long (typically around 4,000 rounds if moderate loads are used- Sin City Precision has a picture of a shot out 6.5 Creedmoor barrel at 2,200 rounds, but state they loaded it hot).

In this post, I’ll be building a custom 6.5 Creedmoor rifle. The heart of a precision rifle is the action, and for this project, a Surgeon 591 short action will be used.

The Surgeon 591 action is a popular choice for custom gun builders. A one piece bolt, integrated rail and recoil lug provide an excellent foundation for custom rifles.

Here are the specifications from Surgeon:

All 591 actions are built with an integral .250” recoil lug and 20 MOA 1913 picatinny rail that runs the full length of the action. A shrouded, side mounted bolt stop is integrated to help prevent accidental releasing of the bolt.

In the middle of the left bolt raceway is an anti-jam rail. The purpose of this rail is to prevent a round from lodging in the raceway when single loading the rifle through the ejection/loading port.

The raceway on the right hand side has an anti-bind rail just below the ejection/loading port. The purpose of this rail is to insure smooth bolt operation as the locking lug passes through the loading port.

The 591SA will work in conjunction with any stocks made for the Remington 700 short action with little to no modification as well as triggers and feeding systems.

I ordered the following parts from Brownells for this project:

I also be using some specialized tools and materials from Brownells:

- 3/8″ high-speed steel turning kit

- 1/2″ high-speed steel threader

- High-speed steel 35 degree profile kit

- Depth micrometer

- Manson chamber reamer

- “go” and “no-go” gauges

- Remington 700 action wrench

- Remington 700 Armorer’s kit

- Do-Drill cutting oil

- Multi-Vise with jaw pads

- Barrel vise

The contents of Rifleshooter.com are produced for informational purposes only and should be performed by competent gunsmiths only. Rifleshooter.com and its authors, do not assume any responsibility, directly or indirectly for the safety of the readers attempting to follow any instructions or perform any of the tasks shown, or the use or misuse of any information contained herein, on this website.

Any modifications made to a firearm should be made by a licensed gunsmith. Failure to do so may void warranties and result in an unsafe firearm and may cause injury or death.

Modifications to a firearm may result in personal injury or death, cause the firearm to not function properly, or malfunction, and cause the firearm to become unsafe.

The first, and most important step is to measure the action to determine the barrel tenon and headspace dimensions. I use a depth micrometer for this critical task.

The barrel is placed in the headstock of the lathe. A spider (four screws spaced at 90 degrees) on each end of the headstock are used to gimbal the barrel so the bore is concentric with the lathe.

A range rod is used to dial in the barrel. I normally start with a .001″ indicator and work down to a .0001″ indicator.

The muzzle end of the barrel is dialed in.

Once both ends of the barrel are dialed in and run true, I use a high-speed steel insert tool to face the end of the barrel and zero the lathe’s digital readout (DRO).

Once both ends of the barrel are dialed in and run true, I use a high-speed steel insert tool to face the end of the barrel and zero the lathe’s digital readout (DRO).

The tenon is turned to the proper length and diameter with a high-speed steel cutter. A micrometer, shown here, is the proper tool to measure the outside diameter of a cylinder, like the barrel shown here.

The tenon is coated in Dykem layout fluid.

The high-speed steel insert threading tool is set up in the lathe. The compound is set at 29.5 degrees and a center gauge is used to make sure the cutter is properly aligned.

Threads are cut at 16 TPI.

I take the time to test fit the action. It should thread on smoothly, with little play. I put a little grease on the threads prior to screwing in on, this prevents the surfaces from galling and the action from getting stuck on the barrel.

A high-speed steel 35 degree profile tool is used to clean up the rear of the tenon.

I use a .705″ form tool in a Manson floating reamer holder to cut the bolt nose recess. The dial indicator on top of the tailstock is resting against the spring clamp. It helps determine the depth of cut.

The finished bolt nose recess (note: the threads look much better in person than they do in the pic above).

Now it is time to set up to ream the chamber. I like using a PTG reamer stop. The stop allows the depth of cut to be adjusted in .001″ increments. For the initial setting, the go headspace gauge is held against the reamer, and the stop adjusted a little short.

I’ll be using a chamber flush system on this barrel. The system attached to the muzzle with a 1/8 NPT fitting. I use a cordless drill and a Q drill to make the clearance hole for the tap.

The 1/8″ NPT tap is used to cut the threads.

And the threaded end of the chamber flush system is attached to the barrel with some Teflon tape to ensure the pressurized oil doesn’t leak.

On this project the reamer is held in a Manson floating reamer holder.

With the oil flowing in one direction through the barrel, the reamer makes short work of the cut. I use Do-Drill cutting oil and it works like a champ.

When the reamer stop contacts the end of the barrel, the chamber is cleaned and the go gauge inserted. A micrometer is used to check the headspace.

As the headspace gets closer to the finished dimension, I start screwing the action back on to the barrel with the headspace gauge in the chamber. A feeler gauge can then be used to measure the gap between the front of the action and the shoulder of the barrel. This dimension is how much deeper the chamber must be cut.

When the chamber is cut to the correct depth, the bolt will close on the go gauge…

…and stay open on the no-go gauge.

…and stay open on the no-go gauge.

Finally, the edge of the chamber is broken and a radius is cut around the bolt nose recess. This radius will assist in feeding.

The barrel is reversed so the crown can be cut. Initially, I dial in off the outside diameter of the barrel.

The barrel is faced.

A range rod is inserted, and the muzzle is dialed in off of the bore.

I make a plunge cut, .090″ deep.

With my compound set at a 45 degree angle, I slowly retract the boring bar, this cuts the “pull back” of the crown.

A light cut is made with a 45 degree counterbore to break the sharp edge of the crown.

The finished crown.

The barrel is removed from the lathe and cleaned. It is torqued onto the action and checked again with go and no-go gauges. The is barrel secured in a Farrell barrel vise for this operation.

Time to prep the stock for bedding. I read somewhere that bedding a rifle was all about the foreplay, this couldn’t be more correct in my experience. First step is to make sure everything fits. Once this is accomplished, the stock surfaces are degreased- this is a critical step.

The action is degreased prior to bedding to allow the masking tape to adhere to the recoil lug. I use 3M fine line tape for the sides and a piece of masking tape for the front. The recoil lug should only be bedded along the rear surface.

A few layers of masking tape are used to center the barrel in the barrel channel. This is also a good time to check that everything fits in the stock one last time. Sometimes, you’ll encounter stocks with a fairly tight lug inlet and the tape on the lug will prevent the action from seating. You don’t want to figure this out the hard way while your epoxy is getting ready to set.

Ample release agent is applied to the metal parts. I like the Acra-Release Aerosol from Brownells. At this point I also apply modeling clay to any voids I do not want filled with epoxy. In addition to making clean up easier, filling the voids with clay prevents mechanical lock up of the action to the stock.

I like putting a little clay snake in front of the recoil lug to make clean up easier.

The Marine-Tex is carefully mixed and applied to the bedding surfaces.

The stock is lowered into place. I screw the bottom metal to the action with the standard stock screws. I find this is the best method and works better than longer screws.

A little bit of time with some cotton swabs and paper towels and the action is cleaned up.

Once the Marine-Tex has been allowed to cure for at least 24 hours, the action is removed from the stock. The excess bedding compound is cleaned with an end mill in the milling machine.

The two bottom metal screw holes will typically have some epoxy in them. I chase these holes with a chucking reamer to clear this out.

The action and stock are ready to be finished. I coated the metal parts of this rifle with black Cerakote. The stock was coated in olive drab Duracoat.

The excellent Nightforce BEAST 5-25×56 FFP scope finishes this rifle off. Does it shoot?

Yes it does! Five rounds of 136 grain Scenar-L in Hornady brass at 100 yards, prone, from a bipod with rear bag.

The rifle shoots like a dream. The Surgeon action cycles smoothly, the Timney trigger has a crisp break and the Nightforce BEAST provides an excellent sight picture. All with the moderate recoil of the 6.5 Creedmoor. I think I have a new go-to rifle!

Follow Rifleshooter.com on Facebook!

Some more Red Hot Gospel!

Just like the one my Grandmother Alice gave me for my birthday. I REALLY miss her as she was a wonderful lady! Grumpy

Some more Red Hot Gospel there!

Stevens 1915 Favorite

In 1955, Bill Ruger went from his .22 Single-Six single-action revolver to a full-sized single-action with his .357 Blackhawk. Basically the same size as a Colt Single Action, the Blackhawk utilized the coil spring action of the Single-Six along with a flat-topped frame with a fully-adjustable Micro rear sight matched up with a ramp front sight on a 4-5/8″ barrel. A longer 6-1/2″ barrel was soon offered and then, very rarely, a 10″ version. They never did offer the standard Colt SAA 5-1/2″ and 7-1/2″ so I had to make my own, which I did several times over the years. The .357 Blackhawk immediately became popular with outdoorsmen and Elmer Keith reported Ruger planned to soon offer it not only in .44 Special but .45 Colt as well. As often happens, something occurred to derail “soon.” That something was the .44 Magnum’s arrival in late December 1955.

A New Revolution

At the NRA Show in 1956, Ruger displayed three .44 Magnum Blackhawks in barrel lengths of 4-5/8″, 5-1/2″ and 7-1/2″. At least in the beginning of the .44 Magnum, Bill Ruger’s prototypes were in the three standard Colt SAA barrel lengths. However, when he went to production, the standard barrel length was 6-1/2″ and very rarely were 7-1/2″ and 10″ versions offered. No 5-1/2″ versions were ever cataloged. Keith looked at the prototypes and told them the cylinder was too short to accept his loads and the frame was too small for the pressure of the .44 Magnum. He did tell Bill Ruger he would like the short-barrel version to use as a .44 Special. Bill told him to pick it up at the end of the show; however, it got packed up too quickly for this to happen and subsequently Keith was proved correct as Ruger decided to do more testing. One of those first .44 Magnum Blackhawks blew up with a proof load.

Ruger went back to the drawing board and, as Keith had suggested, increased the size of the frame and cylinder. In the process, the idea of a .44 Special on the original .357 Magnum Blackhawk died and when Ruger brought out a .45 Colt Blackhawk in 1970, the .44 Magnum-sized frame was used. It would be over a half-century before a .44 Special Ruger Blackhawk arrived.

In 2005 Ruger brought out the 50th Anniversary Model of the .357 Blackhawk. Since the .357 has been on the larger frame since 1972, it would have been quite easy for Ruger simply to use this for the special occasion. I’m certainly glad they did not. Instead, Ruger went retro and the Anniversary Model, although it is built with the New Model transfer-bar action, is otherwise a dead ringer for the original .357 Blackhawk.

It is not only the same size as the 1955 Blackhawk, it also went back to the original Colt Single Action grip frame, known as the XR3 frame, which had been lost with the “improved” XR3-RED grip frame. This frame arrived with the change to the Old Model Blackhawk in 1962. Now finally, the stage was set for a Colt SAA-sized Ruger .44 Special. I talked to the then-president of Ruger about this and he didn’t say yes but he also did not say no.

Take The Long Way

It finally did happen but in a slightly roundabout way, thanks to Lipsey’s. Ruger actually began doing what they had intended to do more than 50 years earlier. The .44 Special Flat-Top New Model Blackhawk was first offered in an all-blued steel sixgun with the choice of 4-5/8″ or 5-1/2″ barrel lengths. Just before the 2009 SHOT Show, Jason Cloessner of Lipsey’s called to inform me they would be offering a special run of Rugers. In itself this is not unusual as Lipsey’s is a distributor that has offered many special editions of several firearms manufacturers over the years.

But this one was special; make that really special. Jason had called to thank me for doing everything I could to keep the .44 Special alive and more importantly, to let me know one of my very special “Special” dreams have come true. Ruger through Lipsey’s would be producing and offering 2,000 .44 Special Flat-Top Blackhawks in 2009. The .44 Special has been a sixgun connoisseur’s cartridge for well over a century and even today some sixgunners still say, “Why a .44 Special when the .44 Magnum is available?” Only those whose heart is in tune really understand.

In the 1950s and 1960s, Ruger offered not only the .357 and .44 Magnum Blackhawks, they also offered .41 Magnum and then later in the early 1970s, the .45 Colt. None of these were ever cataloged with a 5-1/2″ barrel and the latter was the only one offered routinely with a 7-1/2″ barrel length. The original .45 Colt Blackhawk Old Model was only in production from 1970 to 1973 with a total output of just over 23,000 units.

In 1973 all Ruger Blackhawks were changed to the New Model. The New Model replaced the three screws on the side of the frame with two pins and a transfer bar safety was added to the action. There was now a piece of steel between the hammer and the firing pin preventing any negligent discharge. The advent of the New Model action was a great step forward for single-action safety. There are several gunsmiths who can tune a New Model Ruger Blackhawk to absolute perfection.

Handy, Hands Down

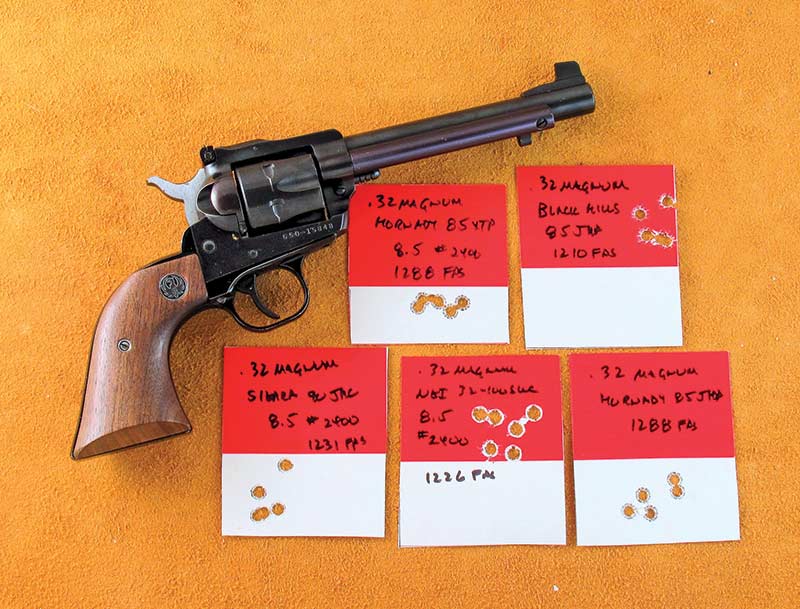

It has been more than 65 years since I purchased my first Ruger Single Action and many more have been added over these all too quickly passing years. A few years back, I set about the task of coming up with 5-1/2″ Compromise Ruger Single Actions. All four of the original chamberings, .357 and .44 Magnum, .41 Magnum and .45 Colt, were used to build this handiest of single actions.

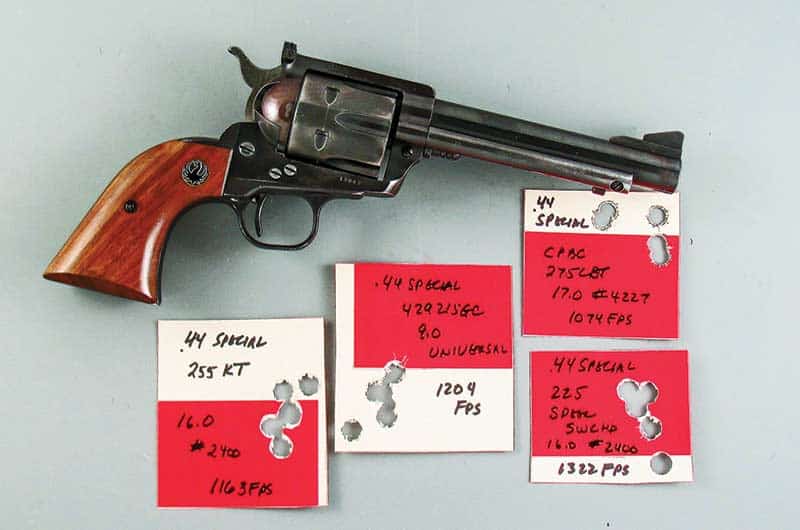

To come up with the .44 Special, I went in two directions. Custom Gunsmith Ben Forkin built several for me using both Ruger .44 Magnum and Colt .44 Special New Frontier barrels on the original-sized crane. All of these were finished with case colored frames and hammers. Ruger liked the idea of a .44 Special New Model Flat-Top so well they became a catalog offering. I also have .44 Specials in both blue and stainless steel finishes.

Lipsey’s and Ruger did not stop there and we soon had a Convertible New Model Flat-Top Blackhawk. Not only is the 5-1/2″ offered in both blue and stainless versions, but with two cylinders, one in .45 Colt and the other in .45 ACP. It could easily be argued that this is the most versatile of Ruger Perfect Packin’ Pistols.

When we try to shoot shorter cartridges in the longer cylinders such as .38 Special and .357 Magnum, we never know how good the results will be until we try. The old .44 Magnum Flat-Top Blackhawk I had cut back to 5-1/2″ also handles .44 Special superbly. Add in the abovementioned 45 Colt/.45 ACP and I have 10 cartridge options in 5-1/2″ sixguns. There is nothing that cannot be handled with one of the choices.