Month: July 2018

Say this poor thing has had a rough life?

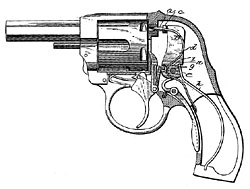

| The Baby Hammerless Revolver by Ed Buffaloe |

|

|

||||||||||||||||||||||||

| The early history of the Baby Hammerless revolver is a bit murky, but the variants of the gun are well documented. My original intent was simply to document the Kolb specimen I collected, but there is so little information about the Baby Hammerless on the internet that I thought I should at least record the various manufacturers and types, and provide what history I can find. Foehl & Weeks Charles G.W. Foehl engaged in the business of making firearms in Philadelphia for a number of years. He was born in the state of Würtemberg, Germany in September of 1840, and immigrated to the United States in 1859. Foehl was apprenticed to Philadelphia gunsmith John Wurfflein, and is said to have worked for Henry Deringer, Jr. before the U.S. Civil War. After the war Foehl worked for the Deringer Rifle and Pistol Works, which was owned by a great-grandson of Henry Deringer, Jr. The firm made cartridge firearms, and its First Model Deringer Revolver utilized some features from Foehl’s first firearms patent, U.S. patent #139,461. The firm also manufactured single shot rifles based on Foehl’s next two patents, which were variants of the Martini action rifle. Foehl died on 4 October 1913, at the age of 73. In 1889 Foehl formed a company with a Philadelphia machinist, Charles A Weeks, to make guns based on Foehl’s patents. They called their company the Foehl & Weeks Firearms Manufacturing Company. In the next few years, they took out several patents together for various features of the revolvers they produced, including U.S. patents #447,219, #468,243, and #471,112. Their revolvers were mostly top-break, in .32 and .38 caliber, some with a grip safety on the front of the grip, some with a safety behind the trigger guard. They were usually marked “THE FOEHL & WEEKS F. A. MFG. CO.” Some were marked “PERFECT” on the topstrap. Foehl & Weeks may have never actually manufactured the Baby Hammerless under their own name, since the company went bankrupt in the financial panic of 1893, and while they continued to be listed in city directories until 1896, there are no Baby Hammerless other than prototypes that can be definitively traced to this period. The two patent dates on the Baby Hammerless are February 2, 1892 and February 4, 1896. The 1892 patent applied to the Baby Hammerless Revolver was Foehl & Weeks’ patent #468,243, and the 1896 patent was Foehl’s patent #554,058. Frank Sellers, in his book Baby Hammerless Pistols, estimates that the entire production of all types of Foehl & Weeks revolvers was no more than a few thousand. The Columbian Firearms Manufacturing Company Columbian was probably formed in 1893, soon after the financial difficulties of Foehl & Weeks became apparent, and almost certainly named in honor of the World’s Columbian Exhibition, held in Chicago in 1893. The president of Columbian Firearms was Henry Ruhland, a Philadelphia financier who just happened to be the bankruptcy referee for Foehl & Weeks (the equivalent of a modern bankruptcy judge). Foehl managed the company, which occupied the same factory that had been previously used by Foehl & Weeks. Essentially, Ruhland and Foehl created a new legal entity which could continue producing firearms using Foehl’s patents, without being liable for Foehl & Weeks’ debts. Later, a half interest in two of Foehl’s patents (#530,759 of 1894 and #554,058 of 1896, the latter of which was on the Baby Hammerless) was assigned to Henry Ruhland. The firm manufactured top-break revolvers nearly identical to those manufactured by Foehl & Weeks. Some were marked “COLUMBIAN F. A. MFG. CO. PHILA. PA. U.S.A./ PAT. DEC. 11.1894 PAT.PDG.” Others were marked “COLUMBIAN AUTOMATIC PAT.PDG./ NEW YORK ARMS CO.” The Baby Hammerless was probably first manufactured by Columbian, though some knowledgeable collectors maintain that all Baby Hammerless models were manufactured after Henry Kolb took over. However, there remains the fact that the early Baby Hammerless had hard rubber grips with vines or scrollwork in the upper circle, whereas Kolb’s revolvers all had a K in the circle. I can’t help but think that if Kolb had made them all, they would all display Kolb’s K. Columbian apparently went out of business in 1897 or 1898, and their guns are rather scarce. Henry M. Kolb Henry M. Kolb was born 16 January 1861 in the Würtemburg state of southern Germany, and was first listed in the Philadelphia city directory in 1895 as a machinist. He claimed in his ads that he founded his firearms company in 1897, which was also the last year the Columbian Firearms Company was listed in the city directory. It is known that Kolb opened a model shop in 1899 and a machinery business in 1900. There is no evidence he ever occupied the address of the old Foehl & Weeks/Columbian com- panies, nor is there any record that he purchased their machinery, though it is possible that he may have done so. Here lies the root of the question as to who made the Baby Hammerless. Other than the hard rubber grips, there are no differences between the Columbian and Kolb Baby Hammerless revolvers–they were probably made with the same equipment. Charles Foehl was also associated with Henry Kolb–they took out several patents together after Kolb entered the firearms business, though none of them were related to the Baby Hammerless. Kolb himself took out two patents in 1910 that relate directly to the Baby Hammerless revolver. The first was #954,190, for a “firing-pin for hammers for firearms,” and the second was #954,191, for a means of mounting and locking the cylinder. Kolb’s business, which apparetly was simply called Henry M. Kolb, became Henry M. Kolb & Company in 1910, and this change may mark the occasion of Reginald F. Sedgley becoming manager of the firm, though this is an inference with no hard data to back it up. R. F. Sedgley, Incorporated Reginald Sedgley was born in England on 3 September 1876 and arrived in the U.S. on 9 May 1894. He is believed to have worked in Philadelphia as a machinist as early as 1896. There is no documentation to show exactly when he worked for Kolb, but it is probable that he began working for him before 1910, several years before Charles Foehl’s death. Sedgley bought out Kolb’s business in 1916, and Kolb returned to the machine shop business by 1917. Sedgley marked his catalogues “R.F. Sedgley, Inc., Established 1897.” Having bought the company, he adopted Kolb’s founding date. While it is possible that Sedgley worked for Kolb as early as 1897, Sellers does not consider it likely. Sedgley was granted two patents for improvements to the Baby Hammerless. The first, #1,216,001, was granted on 13 February 1917 for a new combination mainspring. The second, #1,236,608, was granted 14 August 1917 for a cylinder ejection system. He was also well known for custom gunsmith work, converting 1903 Springfields into sporting guns and sniper rifles, and for his flare gun. Sedgley died on 30 March 1938. Variants of the Baby Hammerless Revolver I despair of making a complete list of Baby Hammerless variations, because the sheer number of them is overwhelming and sometimes confusing. For the most complete coverage available please see Frank Sellers’ book, Baby Hammerless Revolvers. I will cover the high points here. Serial numbers for the Baby Hammerless revolvers are usually found stamped into the frame under the right grip plate.

The gun shown here had both grips broken. I was able to repair them with black epoxy putty, which you can easily see on the rear portion of the left side grip. The gun must have been reasonably well made, as it still functions despite its age. This one is marked with serial number 475. However, Sellers states that duplicate serial numbers are often encountered. It seems that numbers regularly ran from 1 to 999, and then started again at 1.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| References Baby Hammerless Revolvers, by Frank M. Sellers. Privately Printed: 2004. Pistols of the World, by Ian V. Hogg & John Walter. Krause Publications, Iola, WI: 2004. “R.F. Sedgley, Inc.,” by Pete Dickey. American Rifleman, June 1984. Special thanks to Homer R. Ficken for researching information about Charles Foehl. |

||||||||||||

| Copyright 2008-2011 by Ed Buffaloe. All rights reserved. Click on the pictures to open a larger version in a new window. |

||||||||||||

From the hard wear shown by it. I bet this old timer has some stories to tell!

The Dogs of War vs. ISIS Jihadis

The hero Alsatian was accompanying the troops on a training exercise in the north of the country when their convoy of four vehicles came under fire from extremist militants.

One of the SAS cars was destroyed by a homemade bomb and the outnumbered forces were forced to split up and take cover.

With the ISIS fighters pinning the British troops down using two heavy mounted machine guns, an American soldier who was with the group released the snarling dog.

That’s like opening a can of whoop-ass, only furrier.

It charged at the attackers, dodging bullets before taking down one of the jihadis and ripping his neck and face.

It then turned its attention to another extremist, savaging his arms and legs in a frenzied assault.

The jihadis, who are thought to have never seen an Alsatian before, fled the scene screaming, allowing the SAS team to call in air support.

Good dog.

The team then made their way to safety with the dog, who is now being treated by the troops as a hero.

Ya think? Bravo Zulu Kilo Niner.

“A snarling Alsatian running at you is very frightening and probably not something the jihadis had encountered.

“The dog did its job and returned to its handler worth its tail wagging.”

This made me laugh out loud. I can just imagine what the dog was thinking in his doggie brain. Didja see what I did? Didja? Didja? Can I do it again? At least, that’s what Wolfgang would be thinking.

This moment of awesome is brought to you by a heads up from the Queen Of The World, who knows a thing or two about German Shepherds.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

As you can guess I am not a huge fan of my hopefully soon EX Senator from California!